Precision Machining Solutions Across Australia

Fedele Autocore delivers exceptional CNC turning services throughout Australia, specializing in precision-machined cylindrical components and custom turned parts. Our advanced manufacturing capabilities combine state-of-the-art technology with decades of expertise to produce high-quality components that meet the most demanding specifications.

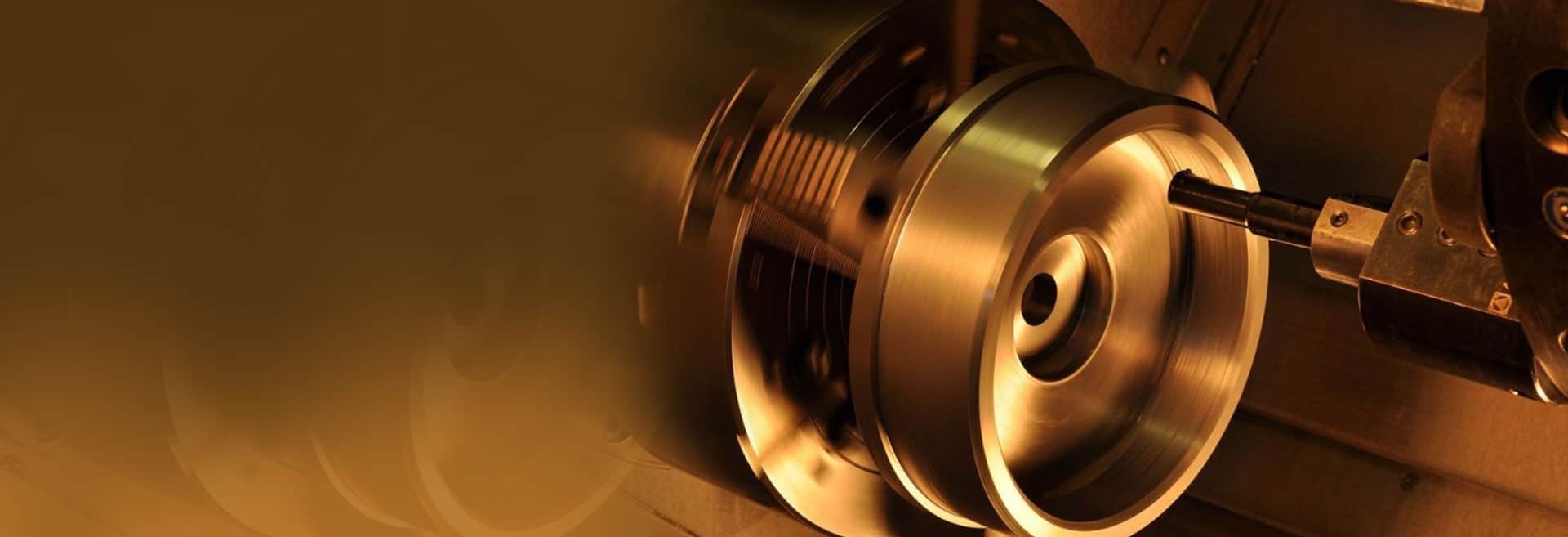

CNC turning is a sophisticated subtractive manufacturing process where raw material is rotated on a spindle while precision cutting tools remove material to create the desired shape. This method excels in producing cylindrical, conical, and complex rotational geometries with exceptional accuracy and surface finish quality.

CNC turning utilizes computer-controlled lathes to rotate workpieces while stationary cutting tools precisely remove material. Unlike CNC milling where the cutting tool rotates, turning operations involve continuous cutting contact as the workpiece spins at controlled speeds. This process is ideal for creating shafts, bushings, pins, fittings, and other cylindrical components with tight tolerances and superior surface finishes.

The turning process can accommodate both external and internal machining operations, enabling the production of complex hollow components, threaded parts, and intricate profiles. Our skilled machinists program each operation to optimize cutting parameters, ensuring consistent quality across production runs.

Achieve tolerances as tight as ±0.005mm with our advanced CNC turning capabilities. Every component undergoes rigorous quality control to ensure dimensional accuracy and geometric precision.

Efficient programming and optimized machining cycles enable quick turnaround times without compromising quality. Perfect for both prototype development and high-volume production runs.

CNC automation ensures consistent part-to-part repeatability, eliminating human error and maintaining quality standards across entire production batches.

Fedele Autocore's CNC turning capabilities encompass an extensive range of engineering materials, each carefully selected and machined using optimized parameters to achieve superior results.

Mild steel, stainless steel 304/316, tool steels, hardened alloys

Excellent strength, corrosion resistance and machinability for lightweight applications

Naval brass, phosphor bronze, silicon bronze

Copper, beryllium copper, electrical grade materials

Our precision CNC turning services support diverse industries across Australia, delivering components that meet stringent quality and performance requirements.

Mission-critical components meeting strict defence standards for military, naval and aerospace applications.

Offshore drilling, subsea equipment, pipeline components and LNG facility parts.

Engine components, transmission parts, performance automotive and motorsport components.

Heavy machinery parts, infrastructure components and construction equipment solutions.

Power generation, renewable energy, grid infrastructure and energy storage components.

Hydraulic cylinders, valve components, pump parts and mining hydraulic systems.

Farm machinery parts, tractor components, agricultural equipment and rural machinery solutions.

Aircraft components, satellite parts, drone components and aerospace prototyping.

Our engineering team reviews your specifications, optimizes designs for manufacturability, and provides technical recommendations to enhance part performance and reduce costs.

We source high-quality raw materials from certified suppliers, ensuring material properties meet your application requirements and industry standards.

Skilled programmers create optimized CNC programs, select appropriate cutting tools, and configure machine setups for maximum efficiency and precision.

Components are machined using state-of-the-art CNC lathes with continuous monitoring to ensure dimensional accuracy and surface finish quality.

Every part undergoes comprehensive inspection using precision measuring equipment, ensuring conformance to specifications and quality standards.

Parts receive appropriate surface treatments or coatings as specified, followed by careful packaging and timely delivery to your facility.

Fedele Autocore maintains rigorous quality management systems to ensure every turned component meets or exceeds customer expectations. Our quality assurance process includes incoming material inspection, in-process monitoring, and final dimensional verification using calibrated measuring instruments.

Experience precision engineering excellence with our comprehensive manufacturing capabilities and commitment to quality:

State-of-the-art CNC turning centers with multi-axis capabilities

Highly skilled operators with extensive experience in precision machining

Serving customers across Australia with consistent quality and delivery

Efficient operations and strategic sourcing deliver excellent value

Engineering assistance from design through production and beyond

Accommodating both small-batch prototypes and large production runs

Streamlined processes ensure rapid delivery without quality compromise

Experience the precision and reliability of Fedele Autocore's CNC turning services. Our team is ready to discuss your requirements and provide solutions that exceed expectations.

Contact us: Discuss your CNC turning requirements with our experienced team and discover how we can support your manufacturing goals across Australia.