Fedele Autocore accelerates your product development with precision CNC prototyping services. From concept to reality in record time, serving aerospace, defence, and agriculture industries across Australia.

Fedele Autocore delivers industry-leading rapid CNC prototyping services across Australia, enabling businesses to accelerate product development cycles and bring innovations to market faster. Our advanced prototyping capabilities combine speed, precision, and flexibility to transform concepts into functional prototypes with exceptional accuracy and quality.

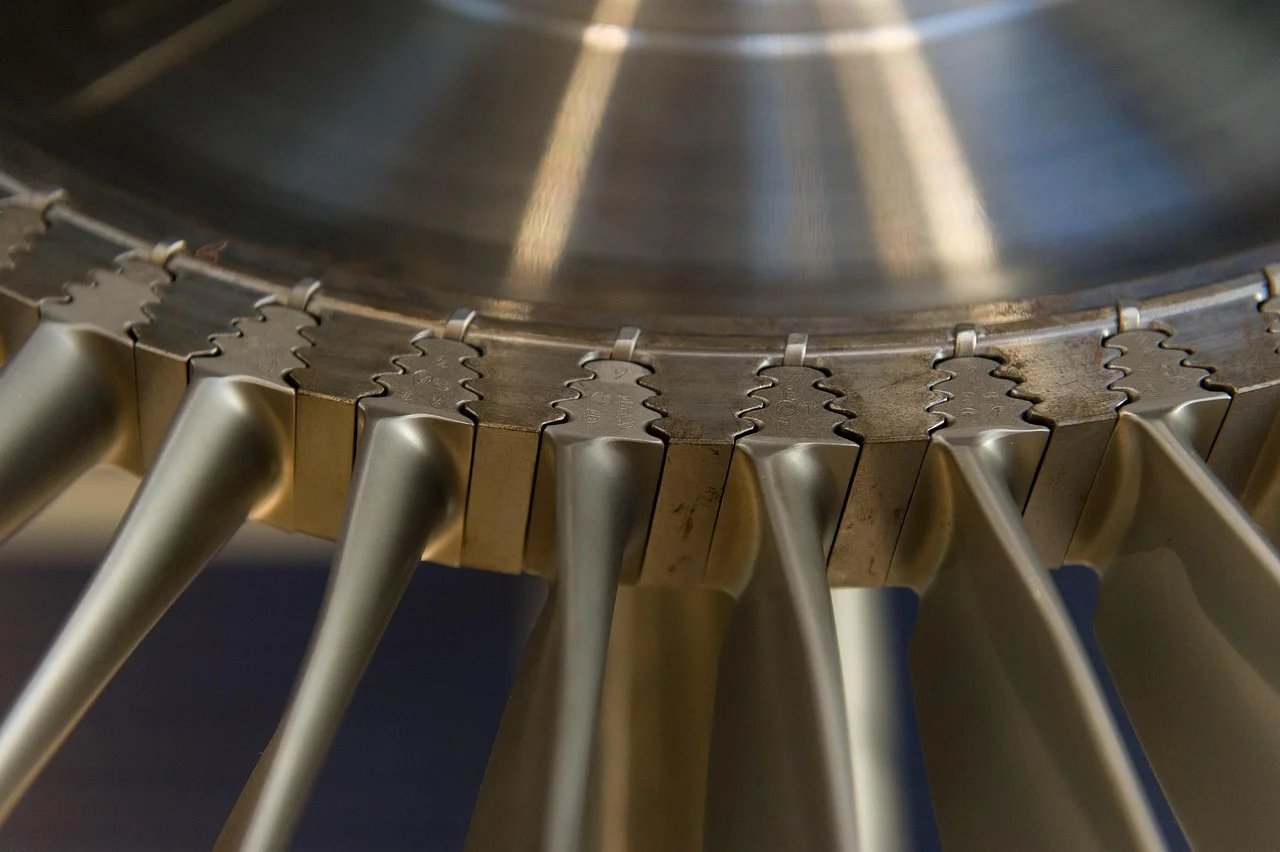

Leveraging state-of-the-art CNC machining technology and extensive materials expertise, we produce high-fidelity prototypes that accurately represent final production parts. From initial design validation to functional testing and iterative refinement, our rapid prototyping services help you reduce development time, minimize costs, and achieve design perfection before committing to full-scale manufacturing.

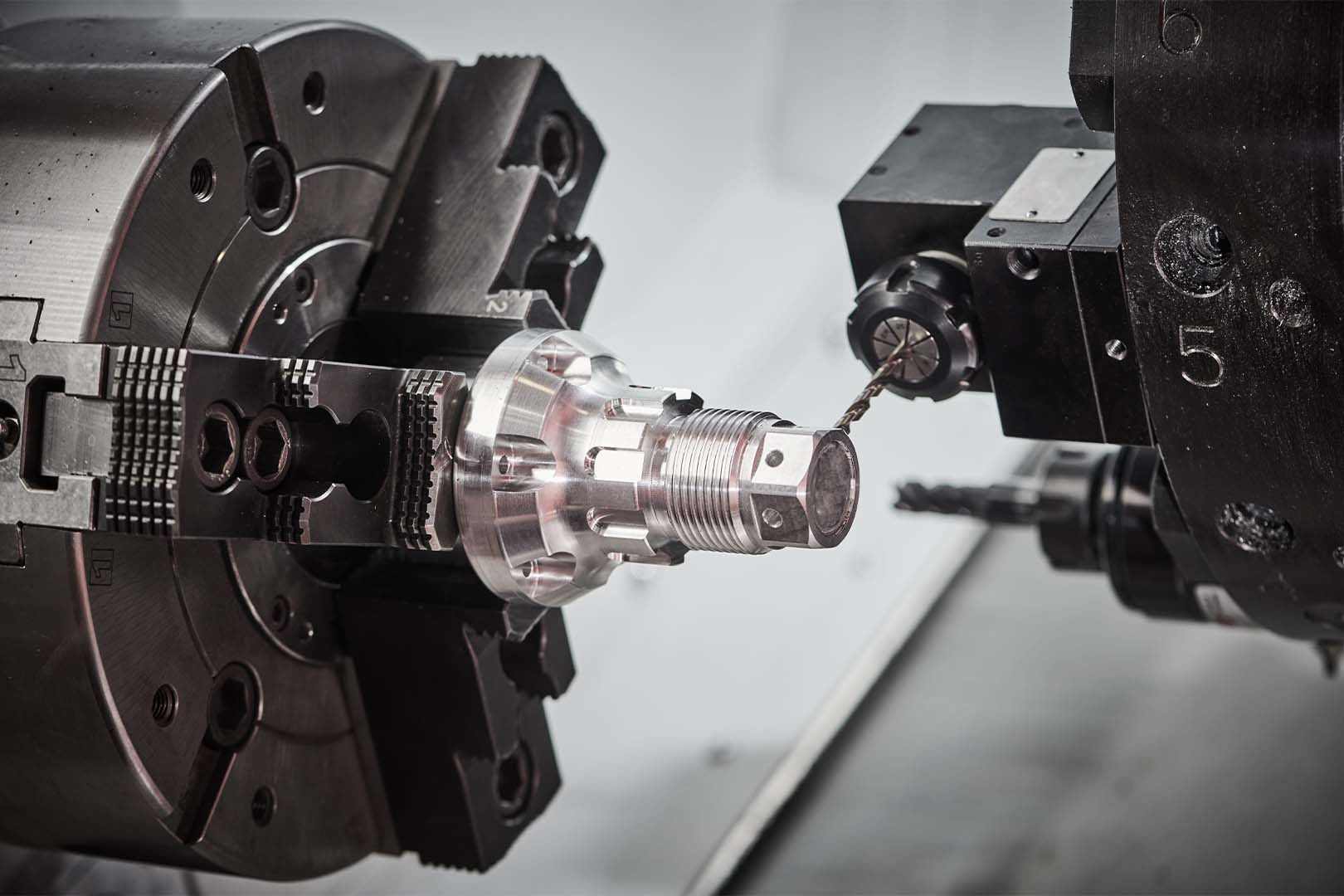

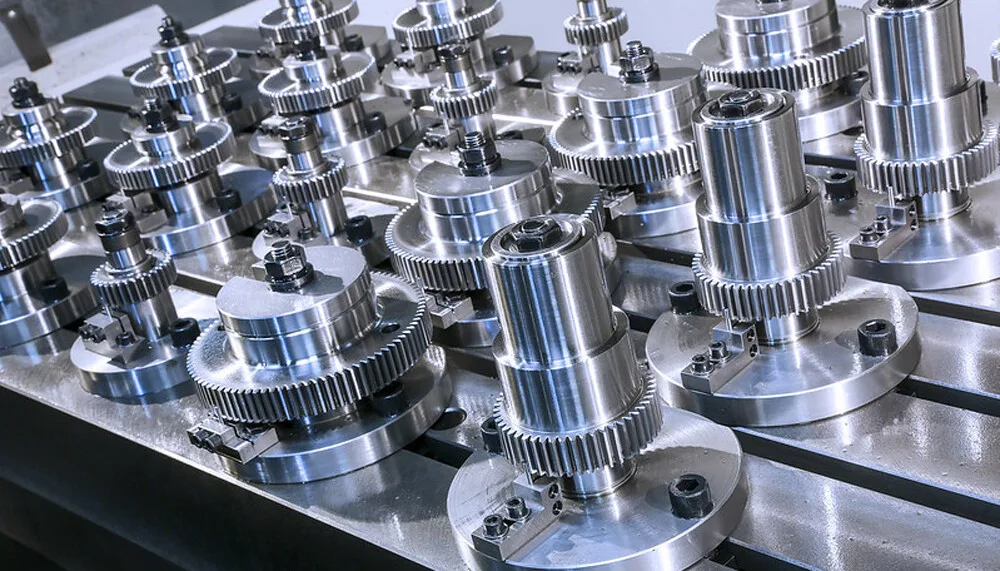

Our rapid prototyping services utilize advanced multi-axis CNC machining centers to create precise functional prototypes in a fraction of traditional timeframes. Whether you need single proof-of-concept models, multiple design iterations, or small-batch pre-production runs, we deliver prototypes that meet your exact specifications with quick turnaround times and exceptional dimensional accuracy.

Transform your CAD designs into physical prototypes in as little as 24-48 hours. Our advanced CNC systems and streamlined processes eliminate traditional manufacturing delays, getting your concepts to market faster.

Achieve tolerances as tight as ±0.005mm with our state-of-the-art CNC machining centres. Every prototype is manufactured to exact specifications, ensuring your design intent is perfectly realised.

Reduce development costs by up to 70% compared to traditional tooling methods. Test multiple design iterations without expensive tooling investments, optimising your product before full production.

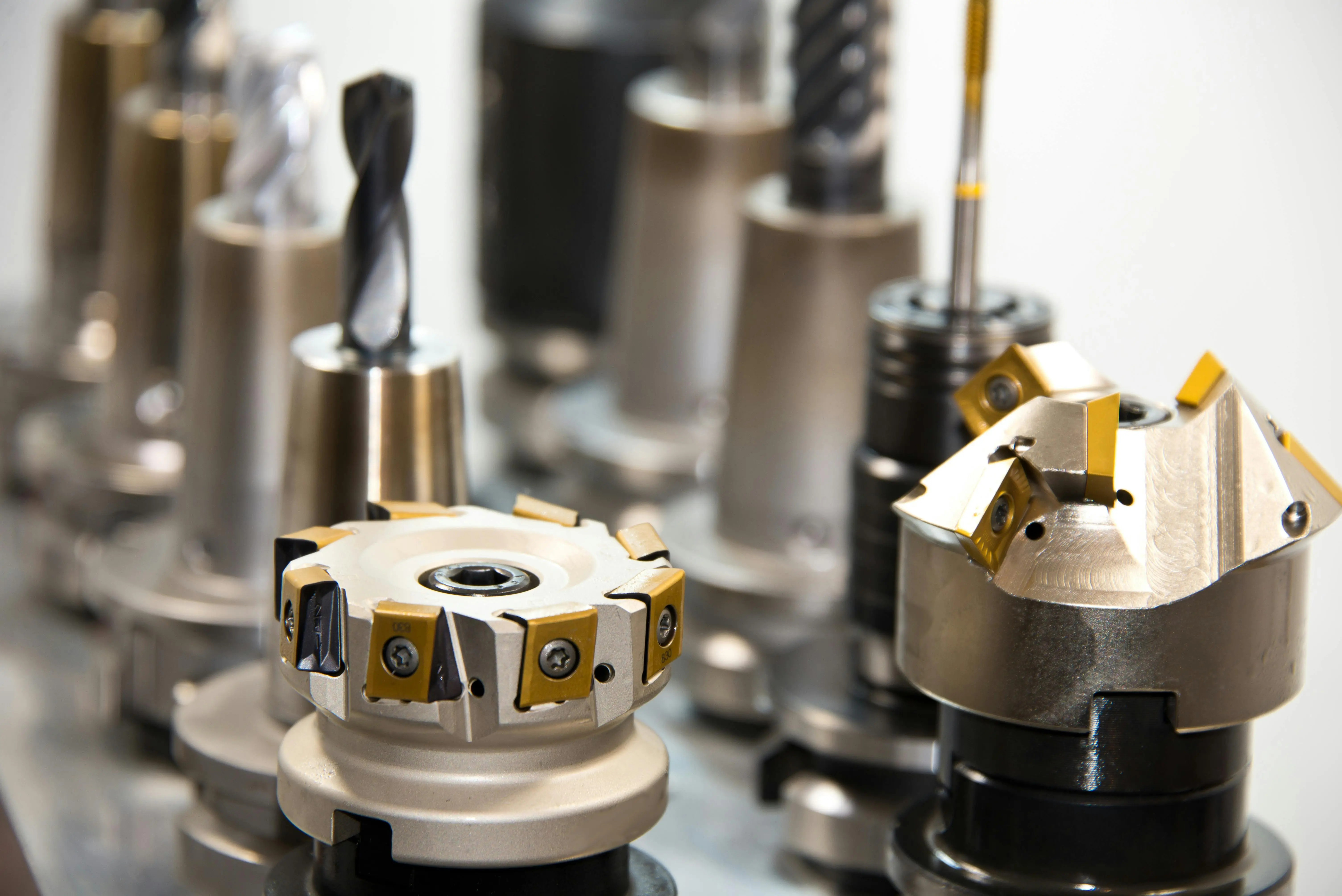

Prototype with production-grade materials including aluminium alloys, titanium, stainless steel, and engineering plastics. Validate both form and function using the exact materials for your final product.

Identify and resolve design issues early in the development cycle. Physical prototyping reveals real-world performance characteristics that digital simulations cannot predict, preventing costly production problems.

Rapidly iterate through multiple design versions with quick prototype modifications. Our flexible manufacturing approach supports agile development methodologies and continuous improvement processes.

Delivering rapid, precise prototypes that accelerate Australian innovation

Fastest Turnaround

Machining Precision

Material Options

First-Time Accuracy

Upload your CAD files through our secure portal. Our engineering team reviews your design for manufacturability and provides immediate feedback on optimisation opportunities.

Receive detailed quotes within 4 hours including material selection, machining strategy, and delivery timeline. Our planning team optimises toolpaths for maximum efficiency.

High-grade materials are selected and prepared according to your specifications. Quality checks ensure material integrity before machining begins.

Advanced CNC centres execute precision machining with real-time monitoring. Multi-axis capabilities enable complex geometries in single setups.

Comprehensive dimensional inspection using CMM technology. Surface finish analysis and material certification ensure prototype meets all specifications.

Secure packaging and express delivery across Australia. Post-delivery support includes design feedback and recommendations for production optimisation.

3, 4, and 5-axis CNC capabilities enable complex geometries and undercuts impossible with conventional machining. Single-setup manufacturing reduces tolerances and lead times significantly.

Advanced spindle technology and optimised toolpaths achieve superior surface finishes while reducing cycle times. Ideal for thin-walled components and intricate details.

Precision machining of miniature components down to 0.1mm features. Essential for electronic housings, medical devices, and precision instrument components.

Machine travel up to 2000mm enables prototyping of substantial components. Perfect for aerospace structures, agricultural machinery parts, and defence applications.

Comprehensive finishing services including anodising, powder coating, and precision polishing. Achieve production-ready surface quality on prototype components.

Complete prototype assembly including fasteners, seals, and sub-components. Deliver fully functional prototypes ready for performance testing and validation.

Flight-critical component development

Accelerate aerospace innovation with prototypes that meet stringent aviation standards. Our aerospace-grade materials and precision manufacturing support everything from UAV components to commercial aircraft parts.

Mission-critical system development

Support Australia's defence capabilities with rapid prototyping of military-grade components. Our secure facilities and certified processes ensure confidentiality and compliance with defence standards.

Farm equipment innovation

Revolutionise Australian agriculture with innovative equipment prototypes designed for harsh operating conditions. Test new concepts before committing to expensive production tooling.

Up & downstream equipment development

Support Australia's energy sector with prototypes engineered for extreme conditions. From offshore platforms to inland refineries, our components withstand corrosive environments and high-pressure applications.

Next-generation vehicle development

Accelerate automotive innovation with rapid prototyping solutions for traditional and electric vehicles. Test new concepts for Australia's evolving automotive landscape including electric vehicle infrastructure.