Precision Machining Services in Sydney

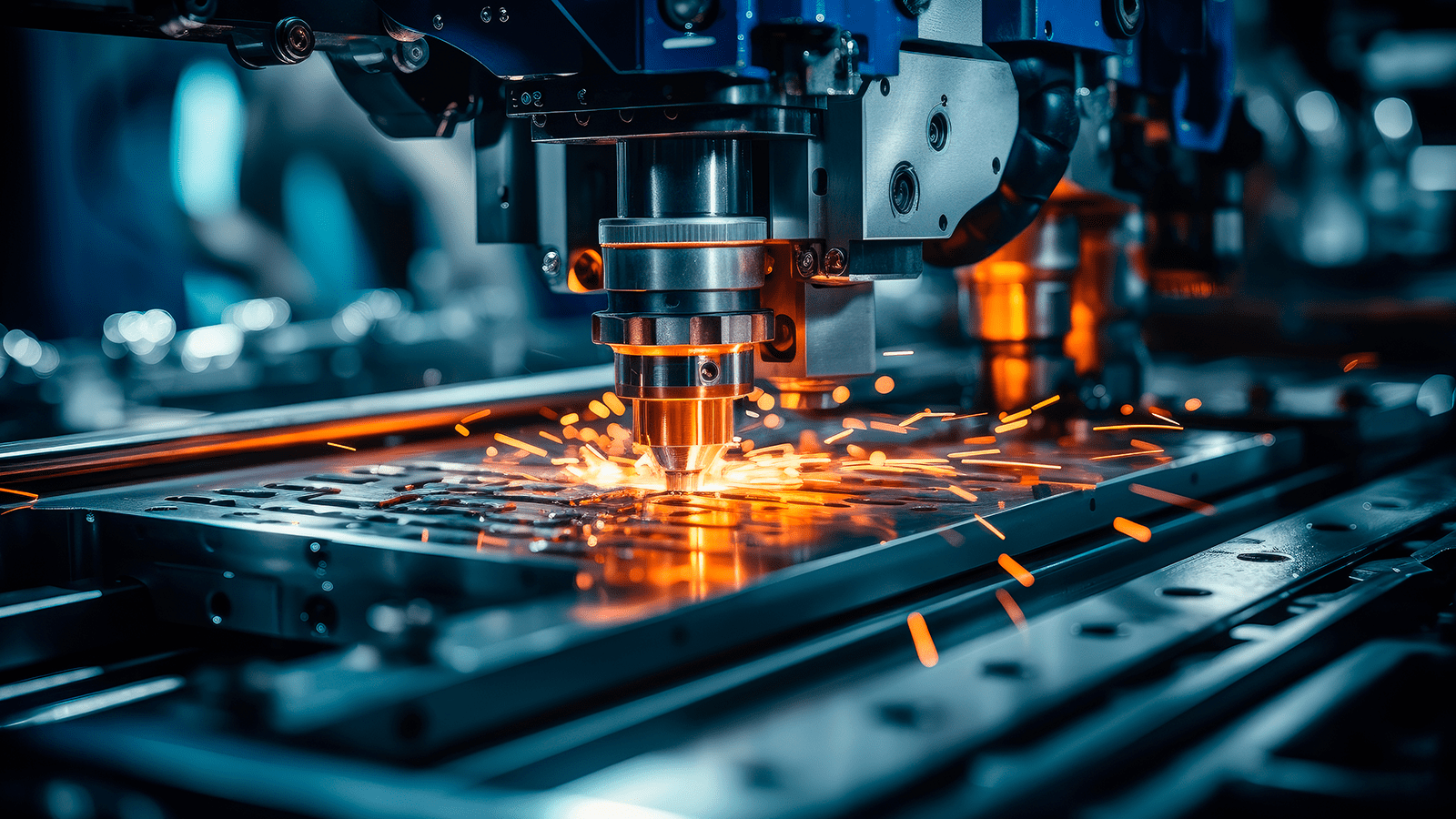

Sydney's technology leaders and defense contractors require the ultimate in manufacturing precision. Our advanced precision machining capabilities deliver components with tolerances measured in microns, supporting critical applications where failure is not an option.

We serve Sydney's most demanding sectors including defense, aerospace, medical technology, and advanced electronics with micron-level precision machining. Our facility features climate-controlled machining environments, vibration-dampened foundations, and the latest in metrology equipment including CMMs and optical comparators. Every component undergoes rigorous inspection and documentation to ensure compliance with the strictest quality standards required by Sydney's premium industries.

Tolerance

Certified

Cleared

Traceability

Sydney's position as Australia's technology and financial center creates demand for precision manufacturing that exceeds normal industrial standards. Our precision machining services have evolved to meet these exacting requirements while maintaining Sydney's expected speed and flexibility.

Sydney's thriving technology sector requires components for semiconductor equipment, optical systems, and precision instruments. These applications demand not only exceptional dimensional accuracy but also superior surface finishes and material properties.

Semiconductor manufacturing equipment components.

Advanced weapon systems and guidance equipment.

Surgical instruments and diagnostic equipment.

Flight-critical components with extreme requirements.

Real-time monitoring and validation of manufacturing processes using advanced statistical methods to ensure consistent quality and identify trends before they become issues.

All measurement equipment and tools are calibrated to standards traceable to national institutes, ensuring absolute accuracy and compliance with international quality requirements.

Specialized manufacturing processes designed for cleanroom environments, meeting the stringent requirements of medical, aerospace, and electronics industries where contamination control is critical.

Complete traceability and compliance documentation for every component, including material certifications, process records, inspection reports, and full audit trails for quality assurance.

Yes, we maintain ISO 13485 certification and follow FDA guidelines for medical device manufacturing with complete documentation and traceability.

We work with major defense contractors and maintain the quality systems and security clearances required for precision defense applications.

While precision takes time, we offer expedited services for urgent requirements, typically 3-5 days for simple precision parts.

Absolutely. We specialize in precision prototyping for Sydney's technology sector, often delivering parts within 24-48 hours.

Yes, our 5-axis precision machining capabilities allow us to maintain tight tolerances on the most complex geometries and compound angles.