Precision Machining Services in Perth

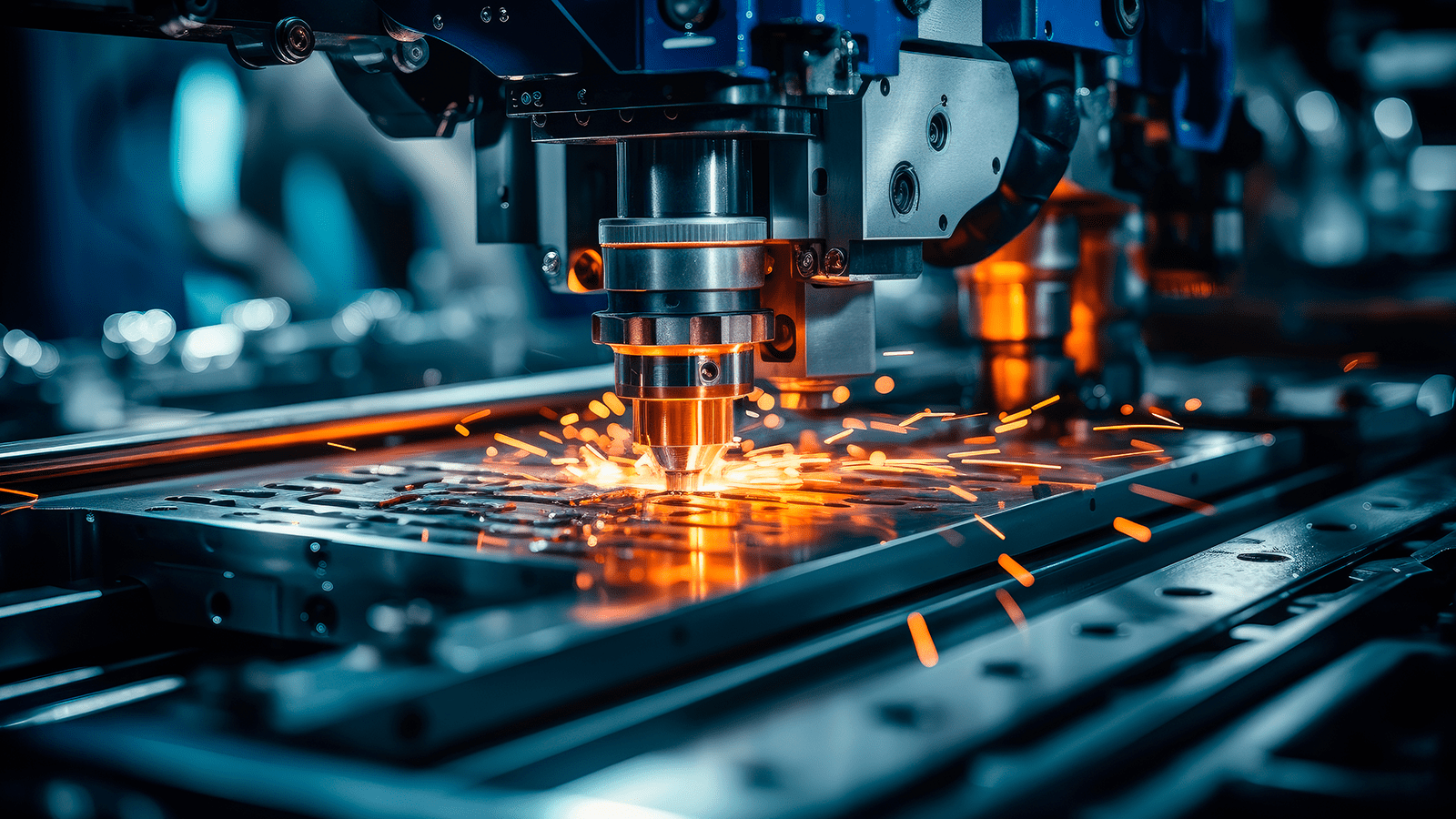

Perth's resource and defense industries require precision components that maintain accuracy under the most challenging conditions. Our specialized precision machining services combine micron-level accuracy with materials and treatments designed for extreme environments.

We engineer components that withstand Western Australia's most demanding applications - from the scorching heat of the Pilbara to the corrosive salt spray of offshore installations and the high-vibration environments of mining equipment. Our expertise includes specialized coatings, heat treatments, and material selections that ensure dimensional stability and performance integrity in temperatures ranging from -40°C to 500°C, high-pressure conditions, and abrasive particulate environments common to Perth's key industries.

To 500°C

Rated

Resistant

Proof

Perth's unique industrial environment creates precision machining requirements that combine the highest levels of accuracy with the durability needed for extreme operating conditions. Our precision machining services have developed specialized capabilities that address these challenging requirements.

Modern mining and offshore equipment increasingly relies on precision components for efficiency and safety. These applications require components that maintain tight tolerances while resisting wear, corrosion, and extreme pressures.

Our extreme-environment CNC machining supports Perth’s most demanding industries with specialized manufacturing solutions for critical applications.

Wear-resistant components for harsh mining environments.

API-compliant parts for offshore and subsea applications.

Corrosion-resistant components for marine environments.

Large-scale manufacturing for industrial equipment.

Advanced environmental testing chambers that simulate extreme conditions including temperature extremes, humidity, vibration, and thermal cycling to validate component performance.

Expertise in machining superalloys, high-temperature alloys, and exotic materials for aerospace, defense, and specialized industrial applications requiring exceptional material properties.

Advanced coordinate measuring machines with integrated temperature compensation systems ensuring measurement accuracy regardless of environmental thermal variations.

Comprehensive pressure testing capabilities for subsea precision components, including hydrostatic testing, burst testing, and cyclic pressure testing to validate deep-water performance.

Yes, we specialize in precision components designed for extreme mining conditions using wear-resistant materials and protective treatments.

We manufacture precision components for subsea applications with full pressure testing and materials certified for extreme depths.

Our facility uses advanced environmental controls and our metrology equipment includes temperature compensation for accurate measurement.

Absolutely. We maintain full material traceability and provide all certifications required for offshore and subsea applications.

We have extensive experience with precision defense applications and maintain the security clearances required for sensitive precision manufacturing.