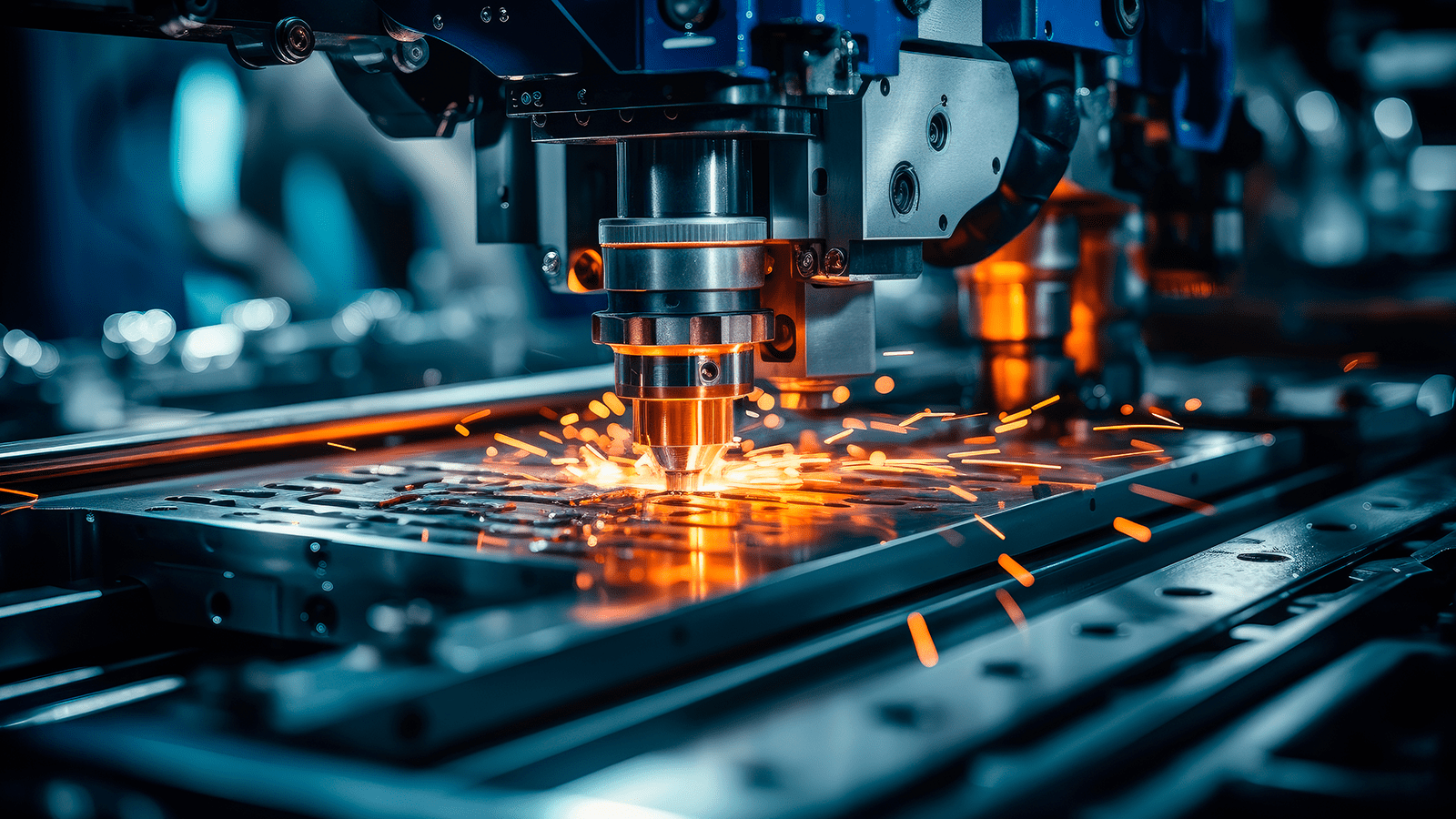

Precision CNC Machining Services in Perth

Precision CNC Machining for Perth's Mining & Industrial Sectors. Perth's resource-driven economy demands robust, reliable components that perform in the world's harshest environments. Our specialized CNC machining services support the mining, oil & gas, and marine industries with components engineered for extreme conditions and long service life.

Strategically located to serve Western Australia's booming resource sector, we specialize in heavy-duty components, wear-resistant parts, and corrosion-resistant solutions for mining equipment, offshore platforms, and industrial machinery. Our Perth facility is equipped with large-capacity CNC machines capable of handling substantial workpieces, and we work extensively with hardened steels, stainless alloys, and specialized materials that withstand abrasive conditions, high pressures, and corrosive environments unique to WA's industrial landscape.

Capacity

Support

Specialists

Local

Perth's unique position as the gateway to Australia's resource wealth creates specific demands for precision manufacturing. Our CNC machining services have evolved to meet these challenges, developing specialized expertise in materials and processes that thrive in extreme environments.

The Pilbara iron ore mines and Goldfields operations require components that can withstand extreme heat, corrosive conditions, and continuous operation. Our CNC machining processes are optimized for wear-resistant materials and include specialized surface treatments.

Our precision CNC machining services support resource-driven industries across Western Australia, delivering components that meet the harshest environmental challenges.

Wear-resistant components for harsh mining environments.

API-compliant parts for offshore and subsea applications.

Corrosion-resistant components for marine environments.

Large-scale manufacturing for industrial equipment.

Specialized equipment and expertise for oversized mining components, large-scale industrial parts, and heavy machinery components requiring robust construction and exceptional durability.

Advanced machining expertise with high-performance materials including Inconel, Hastelloy, titanium alloys, and superalloys for extreme temperature and corrosive environments.

Specialized coating and surface treatment processes including hard chrome plating, thermal spraying, nitriding, and specialized finishes for components operating in extreme environments.

24/7 emergency repair services for remote mining and industrial operations, providing rapid response and critical component restoration to minimize downtime and production losses.

Yes, our Perth facility has heavy-duty machines capable of handling oversized components up to 3 meters in length for mining applications.

Absolutely. We specialize in Inconel, Hastelloy, super duplex stainless steels, and other materials required for extreme offshore environments.

We offer 24/7 emergency services with dedicated personnel for critical mining equipment repairs. We can often provide same-day service for urgent needs.

Yes, we're fully compliant with API standards and maintain all necessary certifications for offshore and subsea applications.

Yes, we have specialized logistics arrangements for shipping to remote locations across Western Australia, including proper packaging for harsh transport conditions.