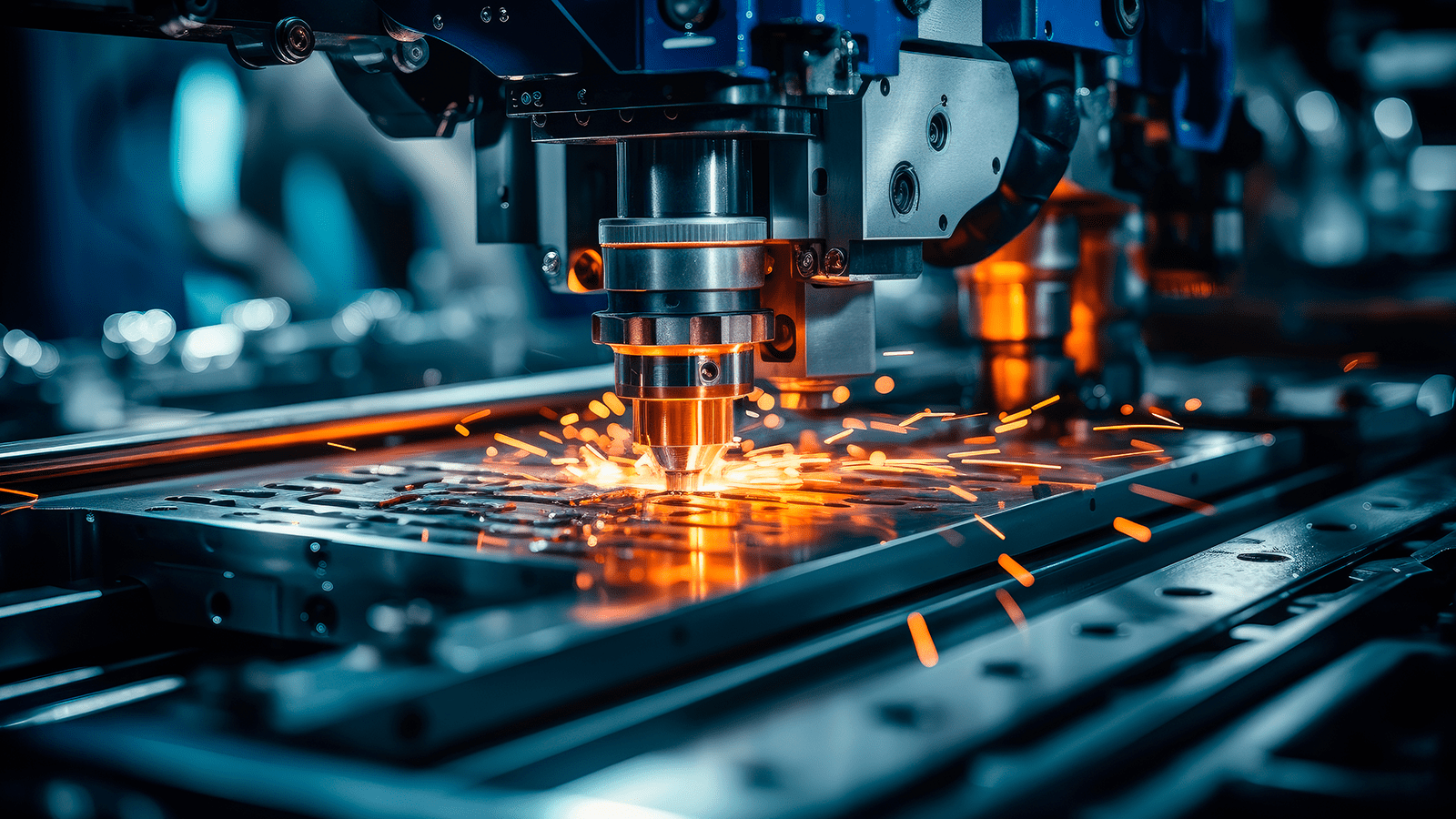

Precision Machining Services in Melbourne

When standard CNC machining isn't precise enough, Melbourne's most demanding industries turn to our precision machining capabilities. With tolerances measured in microns and surface finishes that exceed aerospace standards, we deliver the ultimate in manufacturing precision.

Our ultra-high precision division specializes in micro-machining, complex geometries, and components requiring exceptional dimensional stability. We utilize Swiss-type CNC lathes, 5-axis machining centers with advanced thermal compensation, and metrology equipment capable of measuring to sub-micron levels. Every component undergoes rigorous inspection to ensure it meets the most stringent quality requirements.

Tolerance

Surface Finish

Temp Control

Quality Check

Precision machining represents the ultimate in manufacturing technology, where tolerances are measured in thousandths of millimeters and surface finishes approach optical quality. Melbourne's advanced manufacturing sector increasingly demands this level of precision.

Our precision machining capabilities achieve tolerances as tight as ±0.001mm through advanced machine tools, environmental controls, and meticulous process management. Every aspect of our facility is designed to maintain this level of precision.

Our precision CNC machining services support Melbourne’s most critical industries with advanced manufacturing capabilities and world-class expertise.

Turbine blades and complex structural components.

Offshore drilling, subsea equipment, pipeline components and LNG facility parts.

Complex engine components and body panels.

Precision molds and complex tooling.

For consistent machining quality in all conditions.

Ensuring stable machining for superior precision.

For sub-micron measurement accuracy in all dimensions.

For precise surface verification and quality control.

We routinely achieve ±0.001mm (±1 micron) tolerances for critical applications, with even tighter tolerances possible for specific geometries.

We use coordinate measuring machines (CMMs) and optical measurement systems capable of sub-micron accuracy, with full statistical documentation.

Yes, we specialize in medical-grade materials including titanium alloys and stainless steels with appropriate surface finishes for biocompatibility.

We can achieve mirror-like surface finishes down to 0.025 microns Ra for optical and precision instrument applications.

Absolutely. Our engineers work closely with customers to optimize designs for precision manufacturing and recommend materials and processes.