Precision CNC Machining Services in Melbourne

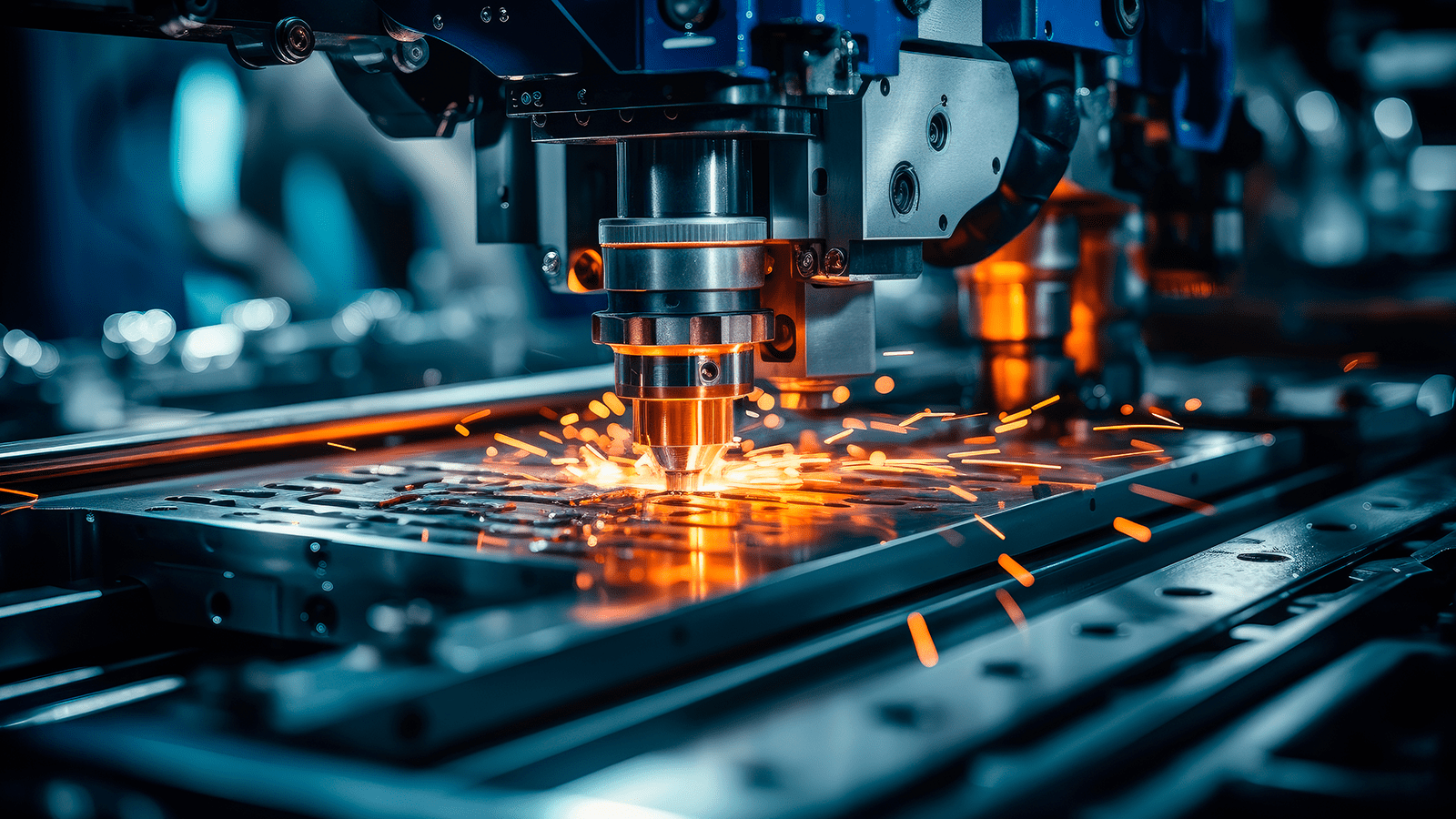

Precision CNC Machining Services in Melbourne. Melbourne's manufacturing sector demands excellence, and our state-of-the-art CNC machining services deliver exactly that. From prototype development to high-volume production runs, we serve Melbourne's aerospace, automotive, medical device, and general manufacturing industries with uncompromising precision and quality.

Our advanced CNC machining capabilities include multi-axis milling and turning, precision grinding, and sophisticated quality control systems. We work with a wide range of materials including aerospace alloys, medical-grade stainless steels, engineering plastics, and exotic metals. Every project benefits from our rigorous quality assurance processes and commitment to meeting the most demanding specifications.

Years Experience

Machining Centers

Tolerance

Production

Melbourne's industrial heritage runs deep, from the automotive manufacturing boom to today's advanced manufacturing renaissance. Our CNC machining facility understands this legacy and continues it with cutting-edge technology and skilled craftsmanship.

Being based in Melbourne means we understand the unique challenges facing local manufacturers. Whether it's navigating complex supply chains during port delays or meeting tight deadlines for seasonal production cycles, our local knowledge gives you a competitive edge.

Our precision CNC turning services support diverse industries across Australia, delivering components that meet stringent quality and performance requirements.

Turbine blades and complex structural components.

Offshore drilling, subsea equipment, pipeline components and LNG facility parts.

Complex engine components and body panels.

Precision molds and complex tooling.

High-speed production capabilities for volumes up to 10,000 pieces with consistent quality and rapid turnaround times.

Advanced machining for complex geometries with rotational features, reducing setup time and improving accuracy.

Simultaneous 5-axis machining for the most complex components, enabling single-setup manufacturing of intricate parts.

±0.005mm standard tolerances with capability for ultra-precision work down to ±0.001mm for critical applications.

Comprehensive component size capability ranging from miniature 1mm parts to large-scale components up to 1500mm in length.

Extensive experience with metals, plastics, and exotic materials including titanium, inconel, and advanced composites.

We work with aluminum, steel, stainless steel, titanium, Inconel, various plastics, and exotic alloys. Our Melbourne facility stocks common grades locally for faster turnaround.

Standard delivery is 5-10 business days. We offer same-day and next-day services for urgent requirements across Melbourne and Victoria.

Absolutely! We work with everyone from Melbourne startups to large corporations. No job is too small - we've helped many Melbourne businesses grow from prototype to production.

We're ISO 9001:2015 certified with AS9100 for aerospace and ISO 13485 for medical devices. All certifications are maintained at our Melbourne facility.

Yes, we specialize in everything from single prototypes to production runs of 10,000+ pieces. Our Melbourne facility is equipped for both low and high-volume manufacturing.