Precision Machining Services in Melbourne

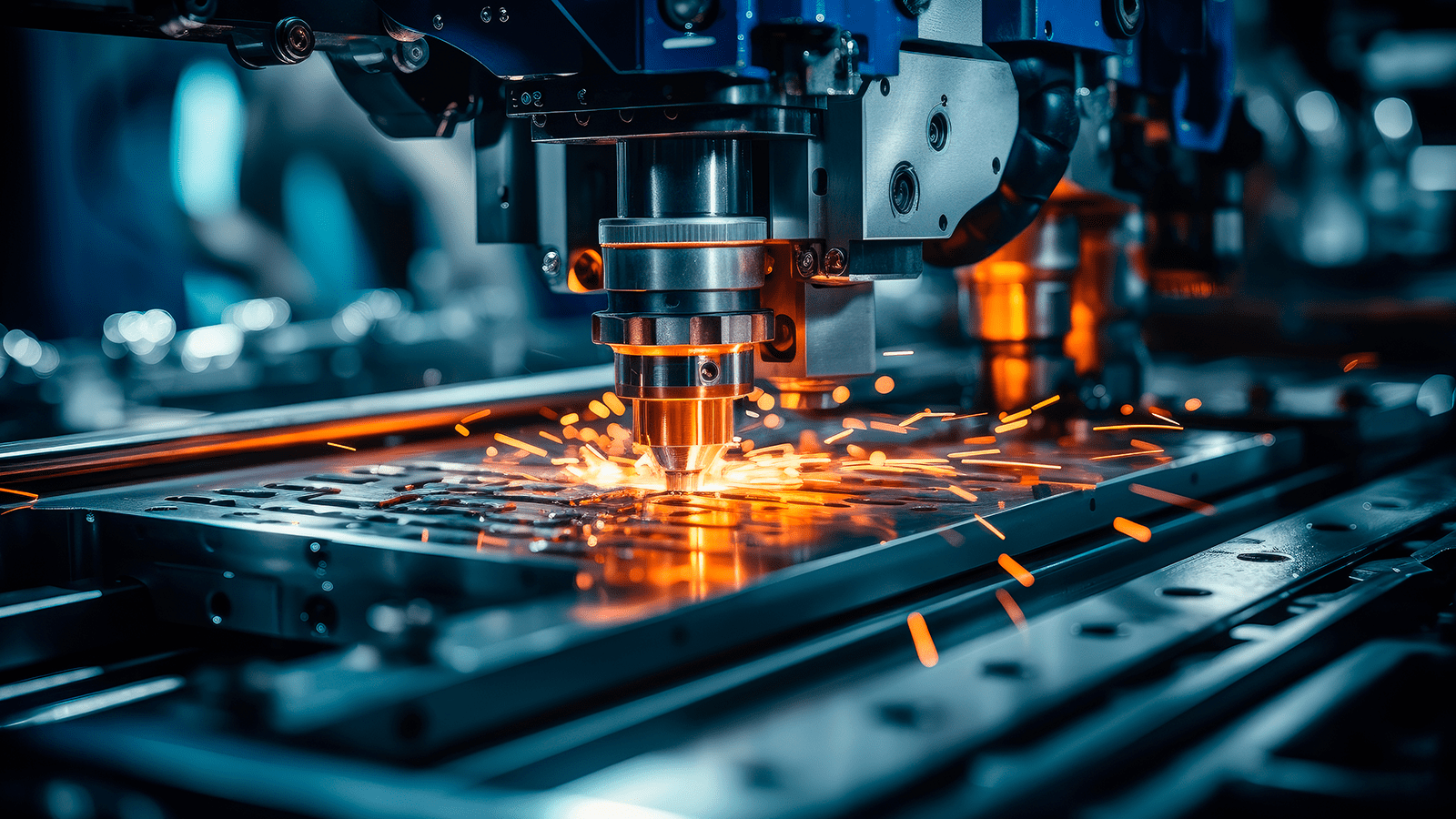

Complex geometries, compound angles, and intricate features demand the ultimate in machining flexibility. Melbourne's most challenging manufacturing projects rely on our advanced 5-axis CNC machining capabilities to achieve what traditional machining cannot.

Our state-of-the-art 5-axis machining centers enable simultaneous machining from five different angles, eliminating multiple setups and reducing production time while improving accuracy. We specialize in complex aerospace components, medical implants, automotive prototypes, and sophisticated tooling that require uninterrupted tool paths and exceptional surface finishes. Our advanced CAM programming and simulation software ensures collision-free operations and optimal machining strategies for even the most complex parts.

Simultaneous

Time Savings

Positioning

Accessibility

5-axis machining represents the pinnacle of CNC technology, enabling the production of complex components that would be impossible or economically unfeasible with traditional 3-axis methods. Melbourne's advanced manufacturing sector increasingly requires these capabilities for competitive advantage.

True simultaneous 5-axis machining allows our machines to move the cutting tool along five different axes simultaneously, creating complex surfaces and features in single setups. This eliminates multiple fixtures and setups, improving accuracy while reducing production time.

Our advanced 5-axis CNC machining services support Melbourne’s most demanding industries with precision, efficiency, and world-class expertise.

Turbine blades and complex structural components.

Offshore drilling, subsea equipment, pipeline components and LNG facility parts.

Complex engine components and body panels.

Precision molds and complex tooling.

Advanced multi-axis control for machining complex surfaces and contours in a single setup, eliminating the need for multiple operations and ensuring perfect geometry.

Sophisticated computer-aided manufacturing software ensures collision-free operation, optimal tool paths, and efficient material removal for complex 5-axis components.

Custom fixtures and advanced clamping solutions designed specifically for complex geometries, ensuring secure positioning and maximum accessibility for 5-axis machining.

Dynamic tool path adjustment during operation for maximum efficiency, reduced cycle times, and optimal surface finishes while maintaining precision and tool life.

5-axis allows complex geometries in single setups, better surface finishes, and access to undercuts and compound angles impossible with 3-axis.

Yes, we specialize in complex aerospace components including turbine blades, structural elements, and engine components requiring 5-axis capabilities.

We can machine virtually any geometry that can be programmed, including deep undercuts, compound angles, and intricate internal features.

All standard materials plus exotic alloys, titanium, Inconel, and advanced composites. Material choice depends on application requirements.

We use advanced CMM measurement, 3D scanning verification, and comprehensive inspection protocols specifically designed for complex geometries.