Precision CNC Manufacturing for the Global Oil & Gas Industry

Fedele Autocore brings decades of precision engineering expertise to the demanding oil and gas sector. Our advanced manufacturing capabilities deliver critical components that withstand extreme pressures, corrosive environments, and rigorous operational demands. From wellhead equipment to pipeline systems, we manufacture parts that ensure safety, reliability, and operational excellence.

Working with specialized materials including duplex stainless steel, Inconel, and other exotic alloys, our state-of-the-art CNC machining centers produce components that meet stringent industry standards including API, ASME, and NACE specifications. We support upstream, midstream, and downstream operations with precision-engineered solutions that maximize uptime and minimize maintenance costs.

Years Experience

Pressure Rated Parts

Industry Standards

Precision Tolerance

High-performance alloys and steels engineered for superior durability and reliability in oil & gas CNC machining applications.

304, 316L grades for superior corrosion resistance

A36, A572 for high-strength structural applications

6061, 7075 for lightweight yet durable components

C-276 for harsh chemical environments

2205, 2507 for enhanced strength

Grade 2, Grade 5 for specialized applications

Our advanced CNC milling capabilities deliver exceptional precision and quality across a wide range of part sizes and complexities.

±0.002mm (±0.0001")

2000mm × 1000mm × 800mm

Ra 0.1µm achievable

Up to 65 HRC

3, 4, and 5-axis simultaneous

Up to 20,000 RPM

Precision machined components engineered for the oil and gas industries, built for durability, safety, and reliability under demanding conditions.

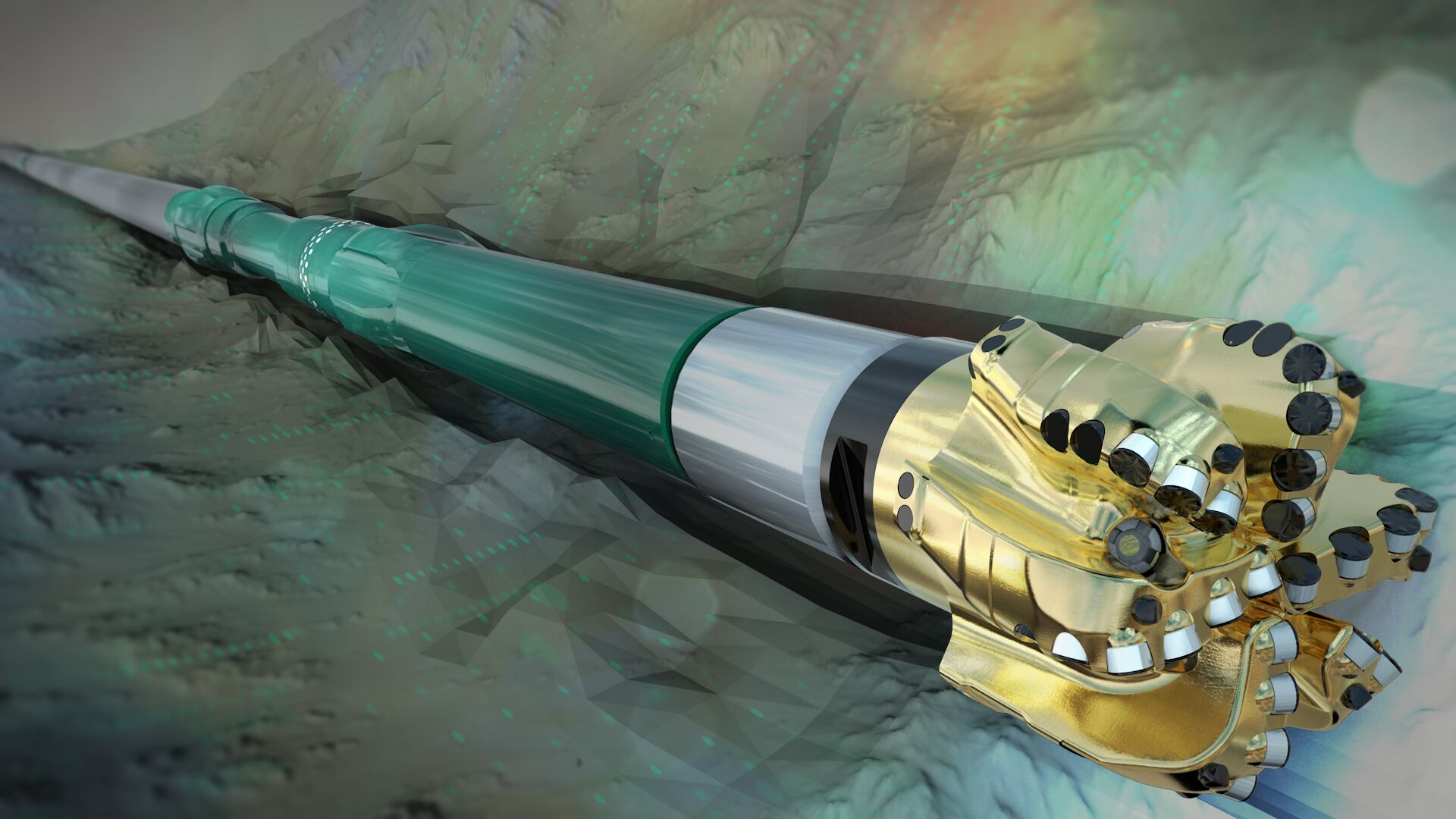

High-precision machined components designed for drilling operations, ensuring reliable performance in extreme downhole conditions.

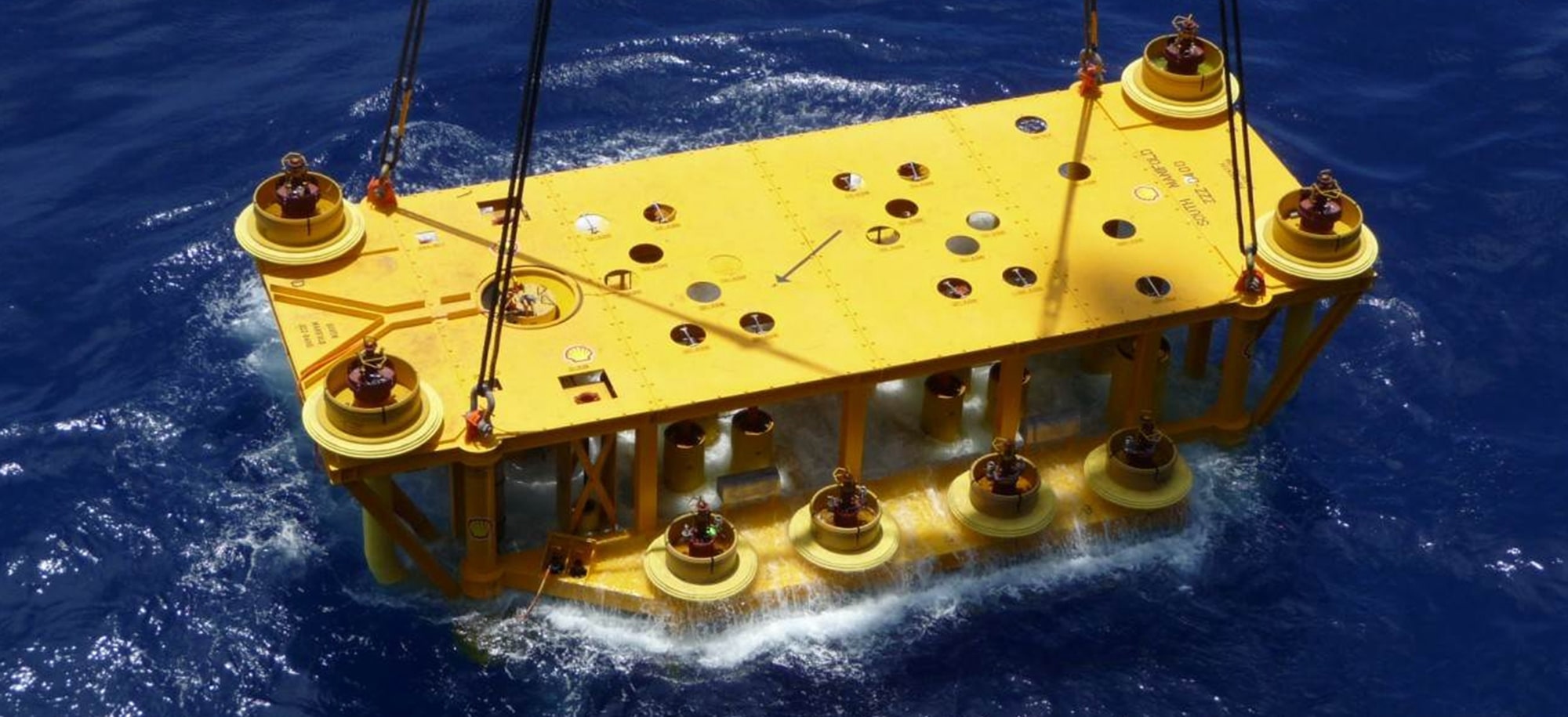

Marine-grade components built to withstand corrosive offshore environments and deliver reliable platform operations.

Precision-engineered subsea components meeting stringent standards for extreme underwater pressure conditions.

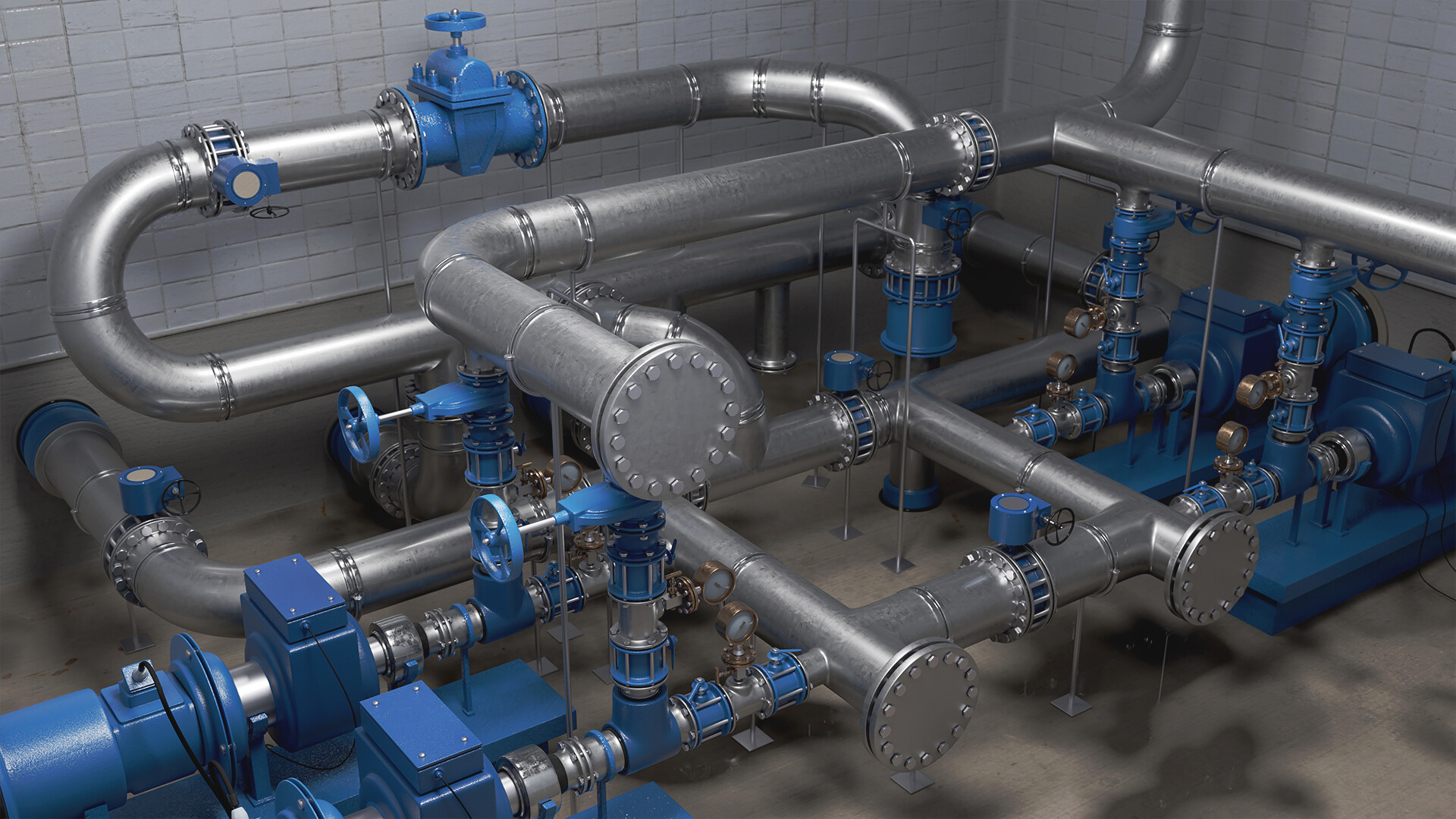

Critical infrastructure components machined to exact specifications, ensuring leak-free operation and structural integrity.

Precision wellhead parts that provide reliable sealing and control for demanding well operations.

High-strength vessel components engineered to withstand extreme stresses and ensure operational safety.

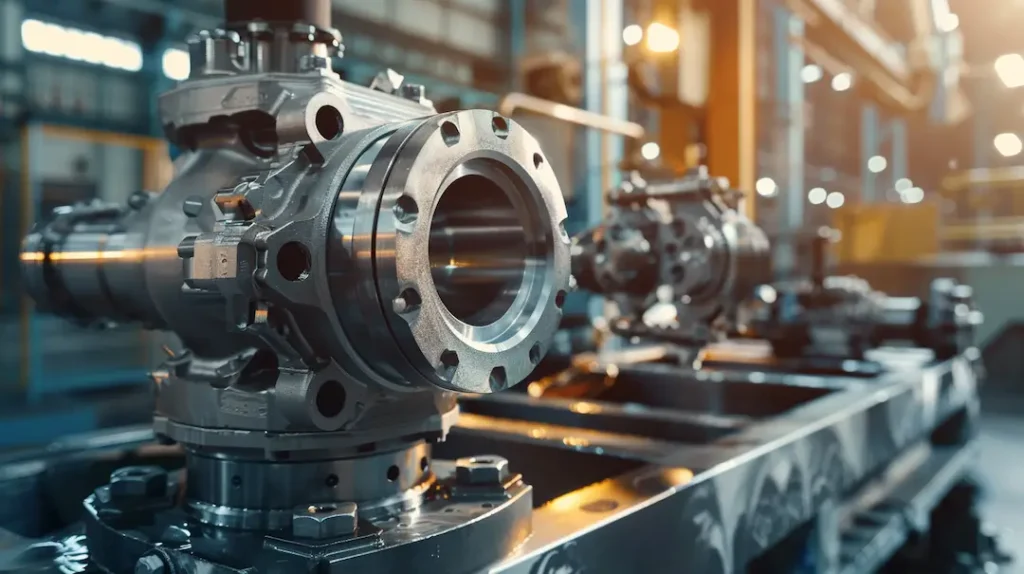

Precision-machined valve bodies designed for flow control, ensuring durability in oil and gas operations.

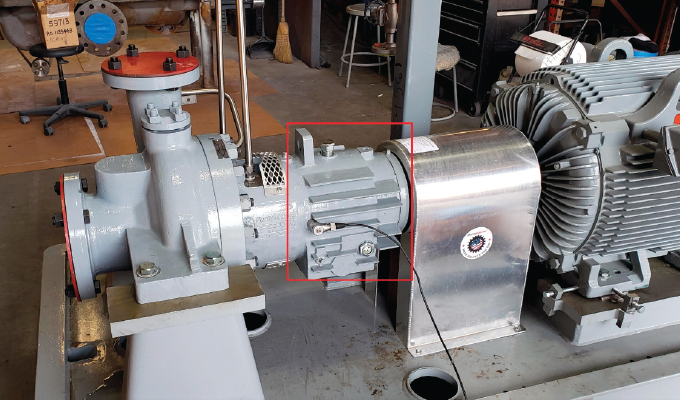

Robust pump housings engineered for continuous operation in harsh oilfield environments.

High-precision compressor components ensuring efficiency, reliability, and long service life.

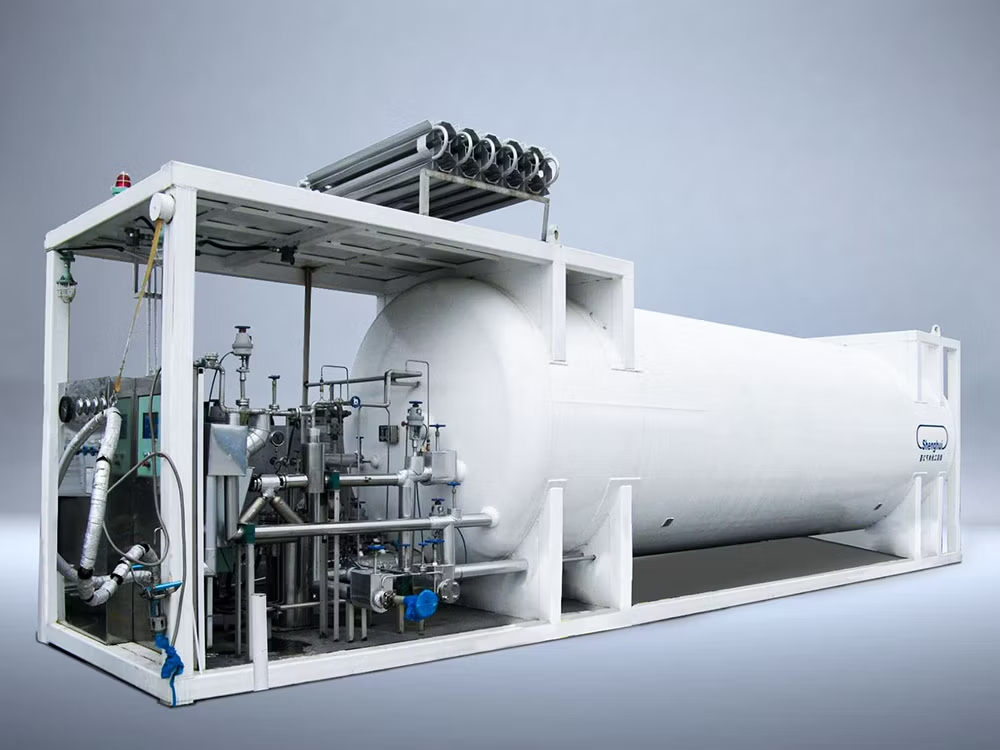

Specialized components designed to withstand cryogenic conditions and high-pressure environments.

Heavy-duty components built for hydraulic fracturing, tolerating high pressures and harsh conditions.

Safety-critical parts for blowout preventer systems, ensuring well control, emergency response, and reliability.

Leading specialist in oil and gas CNC machining and precision manufacturing.

Fedele Autocore stands at the forefront of oil and gas CNC machining. Our advanced CNC machining capabilities deliver precision machined components for the oil and gas industries that exceed the most demanding specifications, achieving tolerances as tight as ±0.001" (±0.025mm).

With decades of expertise in oil and gas CNC components, we work with premium materials including 316L stainless steel, carbon steel, aluminum alloys, Inconel, Hastelloy, and other specialized alloys designed for extreme conditions. Every precision machined component undergoes rigorous quality control to ensure it meets industry standards and exceeds customer expectations.

State-of-the-art CNC machining technology achieving ±0.001" tolerances, experienced engineering team specializing in oil and gas applications, premium materials from 316L stainless steel to Inconel alloys, ISO-certified quality processes, fast turnaround times, and comprehensive testing ensure your precision machined components meet exact specifications every time.

Precision Tolerance Capability

Years of CNC Machining Excellence

Specialized Component Categories

Quality Assured Components

Common questions about our oil and gas CNC machining services and precision components

All precision machined components come with comprehensive quality documentation including material certificates, dimensional inspection reports, surface finish verification, and full traceability documentation.

Lead times vary based on complexity and quantity, but typically range from 2-6 weeks for standard precision machined components. We offer expedited services for urgent requirements and maintain inventory for commonly requested oil and gas CNC components.

Absolutely. We accommodate everything from single prototype components to large production runs, with flexible CNC machining processes to meet your specific volume requirements for oil and gas applications.

Our precision machined components primarily serve the oil and gas industries, including upstream drilling, midstream pipeline operations, downstream refining, offshore platforms, subsea operations, and LNG facilities.

What our partners say about our oil and gas CNC machining and precision components

Engineering Manager - Energy Corp

"Fedele Autocore has been our go-to supplier for critical wellhead components for over three years. Their precision and reliability have never disappointed us, even under the tightest deadlines."

Operations Director - Offshore Solutions Ltd

"The quality of their pressure vessel components is outstanding. Every part meets our exact specifications, and their attention to detail gives us complete confidence in our operations."

Project Manager - Deepwater Drilling Services

"When we needed custom drilling components on short notice, Fedele Autocore delivered exceptional quality ahead of schedule. Their expertise in oil and gas applications is evident in every component."

(+91)-95-700-30000

sales@fedeleautocore.com

Monday - Friday: 8:00 AM - 6:00 PM

Oil and Gas CNC Components