Advanced CNC manufacturing solutions for Australia's hydraulic industry. Delivering exceptional precision, quality, and reliability for critical hydraulic applications.

Fedele Autocore specializes in precision manufacturing of hydraulic system components that deliver exceptional performance under extreme pressure and demanding conditions. Our expertise encompasses hydraulic cylinders, valve bodies, manifolds, piston rods, and custom fittings engineered to exact specifications. We serve industries requiring reliable hydraulic power transmission, from mobile equipment to industrial automation systems.

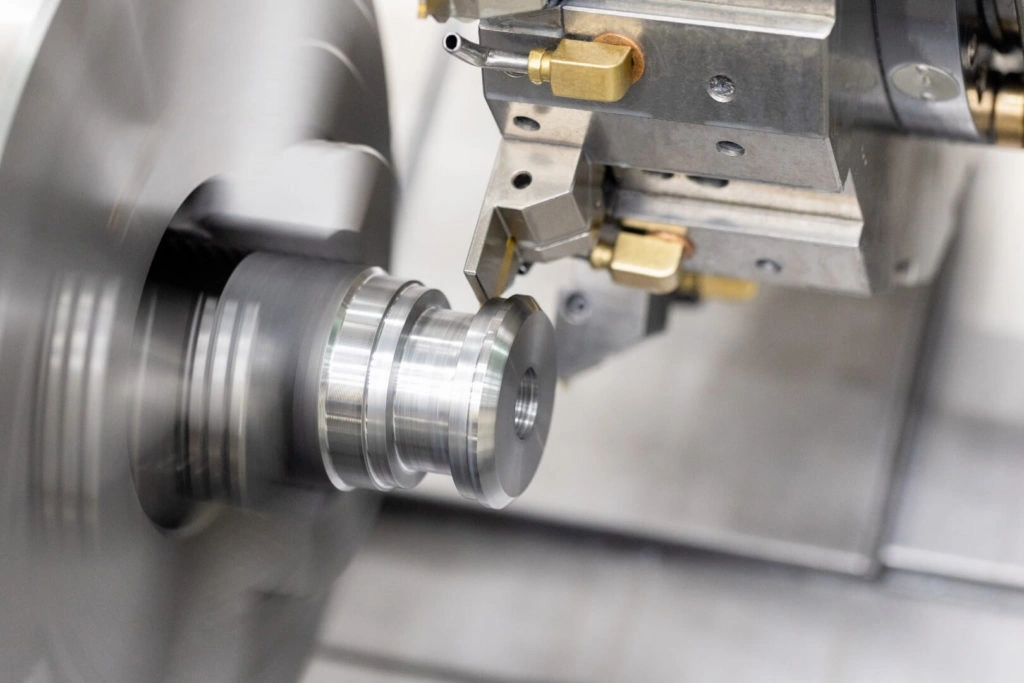

Utilizing advanced CNC machining and precision honing capabilities, we produce hydraulic components with superior surface finishes and tight tolerances essential for leak-free operation and extended service life. Our manufacturing processes include hard chrome plating, precise bore finishing, and rigorous pressure testing to ensure every component meets the highest hydraulic industry standards. We work with specialized grades of steel and engineered materials that withstand high pressures, contamination, and continuous duty cycles.

Years Experience

Pressure Capacity

Surface Finish

Precision Tolerance

Our hydraulic CNC components are manufactured using only the finest materials, specifically selected for their exceptional performance in demanding hydraulic environments.

Superior corrosion resistance, excellent strength-to-weight ratio, and outstanding durability in harsh hydraulic conditions.

High tensile strength, excellent fatigue resistance, and superior hardenability for critical load-bearing hydraulic components.

Aerospace-grade aluminum with exceptional strength, lightweight properties, and excellent machinability for precision parts.

Medium carbon steel offering excellent balance of strength, toughness, and cost-effectiveness for hydraulic applications.

Exceptional wear resistance, natural lubricity, and corrosion resistance ideal for valve components and fittings.

Premium superalloys for extreme temperature and corrosive environments requiring ultimate material performance.

State-of-the-art CNC machinery delivers tolerances down to ±0.001mm, ensuring perfect fit and optimal performance in critical hydraulic systems.

Multi-axis CNC centers, EDM capabilities, and comprehensive quality control systems guarantee consistent, high-quality production.

Efficient production scheduling and dedicated hydraulic component expertise enable rapid delivery across Australia without compromising quality.

We specialize in manufacturing a comprehensive range of hydraulic components including cylinder parts, valve bodies, pump housings, manifold blocks, precision fittings, filter assemblies, and accumulator components. Our expertise covers both standard and custom hydraulic parts for various industries across Australia.

We work with premium materials specifically chosen for hydraulic applications, including 316 stainless steel, 4140 alloy steel, 7075 aluminum, C45 carbon steel, brass and bronze alloys, and specialty superalloys like Inconel and Hastelloy. All materials come with full material certifications and traceability.

Our advanced CNC machinery can achieve tolerances as tight as ±0.001mm (±0.00004") for critical hydraulic components. We maintain strict quality control throughout the manufacturing process to ensure consistent precision across all parts, regardless of batch size.

Yes, our experienced engineering team can work from your drawings, specifications, or even samples to create custom hydraulic components. We also offer design consultation services to optimize your hydraulic system performance and manufacturability.

Standard hydraulic components typically have a 2-3 week turnaround time, while complex custom parts may require 3-4 weeks. We offer expedited services for urgent requirements and maintain clear communication throughout the production process to keep you informed of progress.

Absolutely. All hydraulic components come with comprehensive quality documentation including material certificates, dimensional inspection reports, pressure testing results where applicable, and full traceability documentation. We maintain ISO 9001:2015 certification and can provide additional testing as required.