We've been crafting high-precision automotive parts for demanding applications since 1999. Serving clients across Australia with competitive pricing and uncompromising quality.

Starting as a specialized machine shop, Fedele Autocore has grown into one of the most trusted names in precision automotive component manufacturing. Our founder, Giuseppe Fedele, brought traditional Italian craftsmanship to the automotive industry, combining old-world attention to detail with cutting-edge CNC technology.

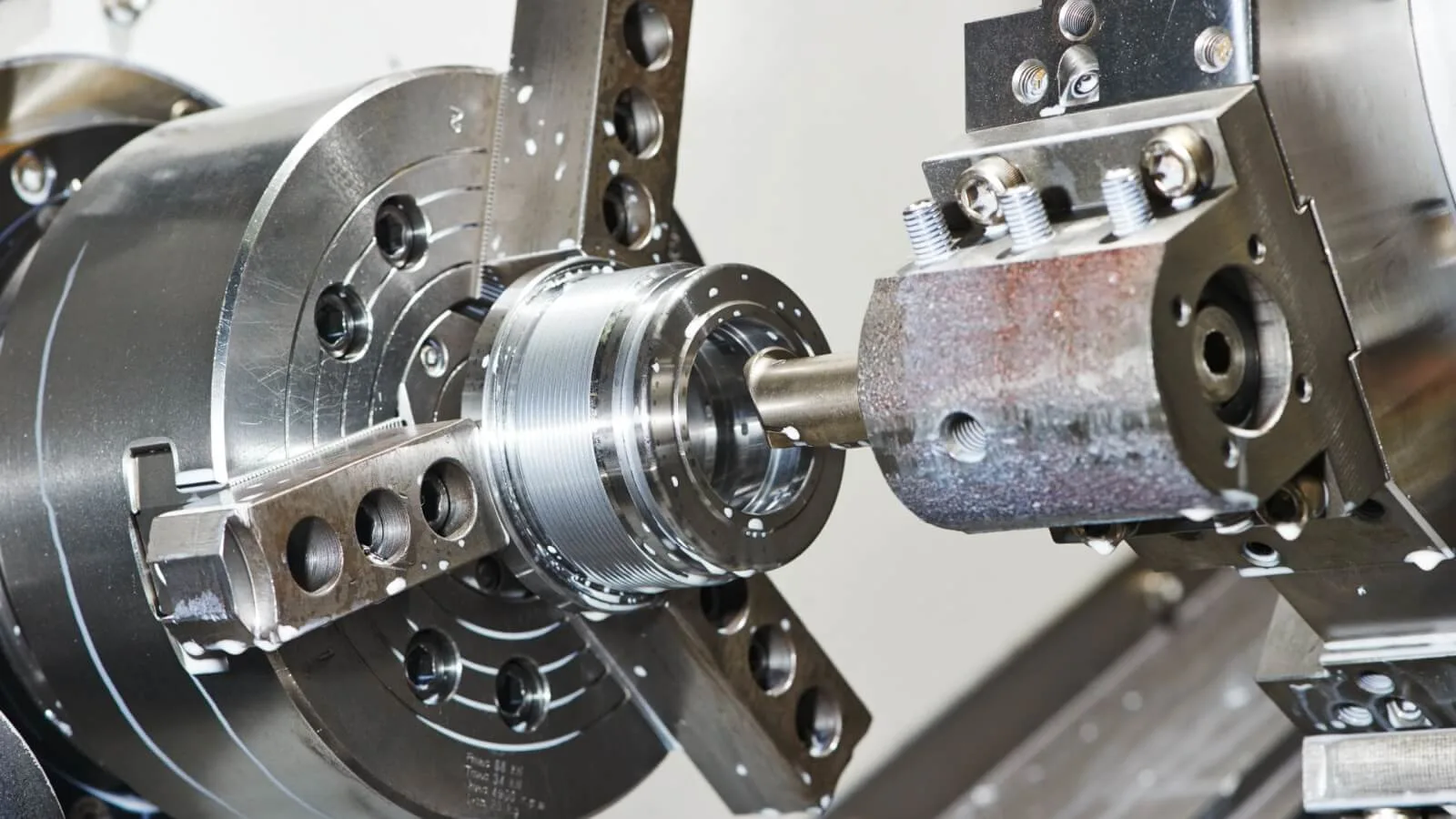

Today, our team of skilled machinists and engineers work with multi-axis CNC centers that can hold tolerances most shops can only dream of. We serve clients across Australia with competitive pricing, supplying components for everything from weekend track cars to professional racing teams.

Years Experience

Precision Tolerance

Components Designed

Certified Quality

From prototype to production, we machine the components that keep vehicles running strong across Australia.

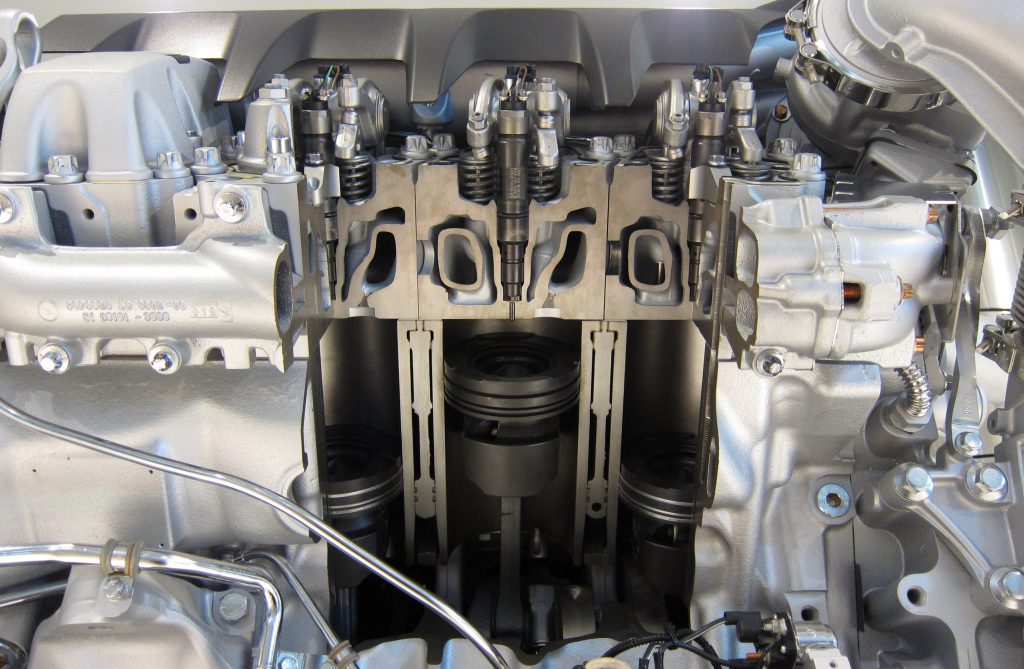

We machine everything from cylinder heads to valve guides with the kind of precision that keeps engines running smooth for years. Our crankshaft work has powered some seriously fast builds.

Gear sets, input shafts, and transmission cases that handle serious torque. Whether it's a street car or race application, our transmission work delivers the reliability you need.

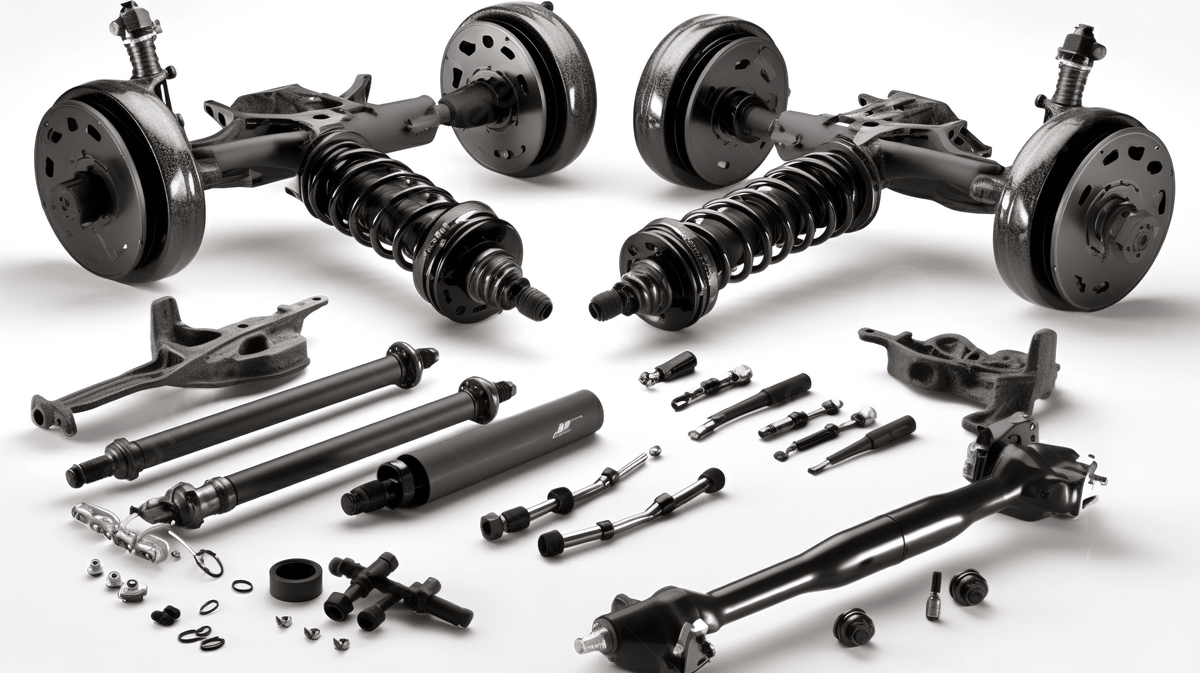

Control arms and mounting hardware that actually improve how your car handles. We've done custom suspension work for hill climbs, track days, and everything in between.

When it comes to brakes, there's no room for compromise. Our rotors, calipers, and mounting hardware are machined to handle the heat and stress of serious braking applications.

Fuel rail components, injector housings, and pump parts that deliver consistent fuel flow. Clean machining and proper material selection make all the difference in fuel system reliability.

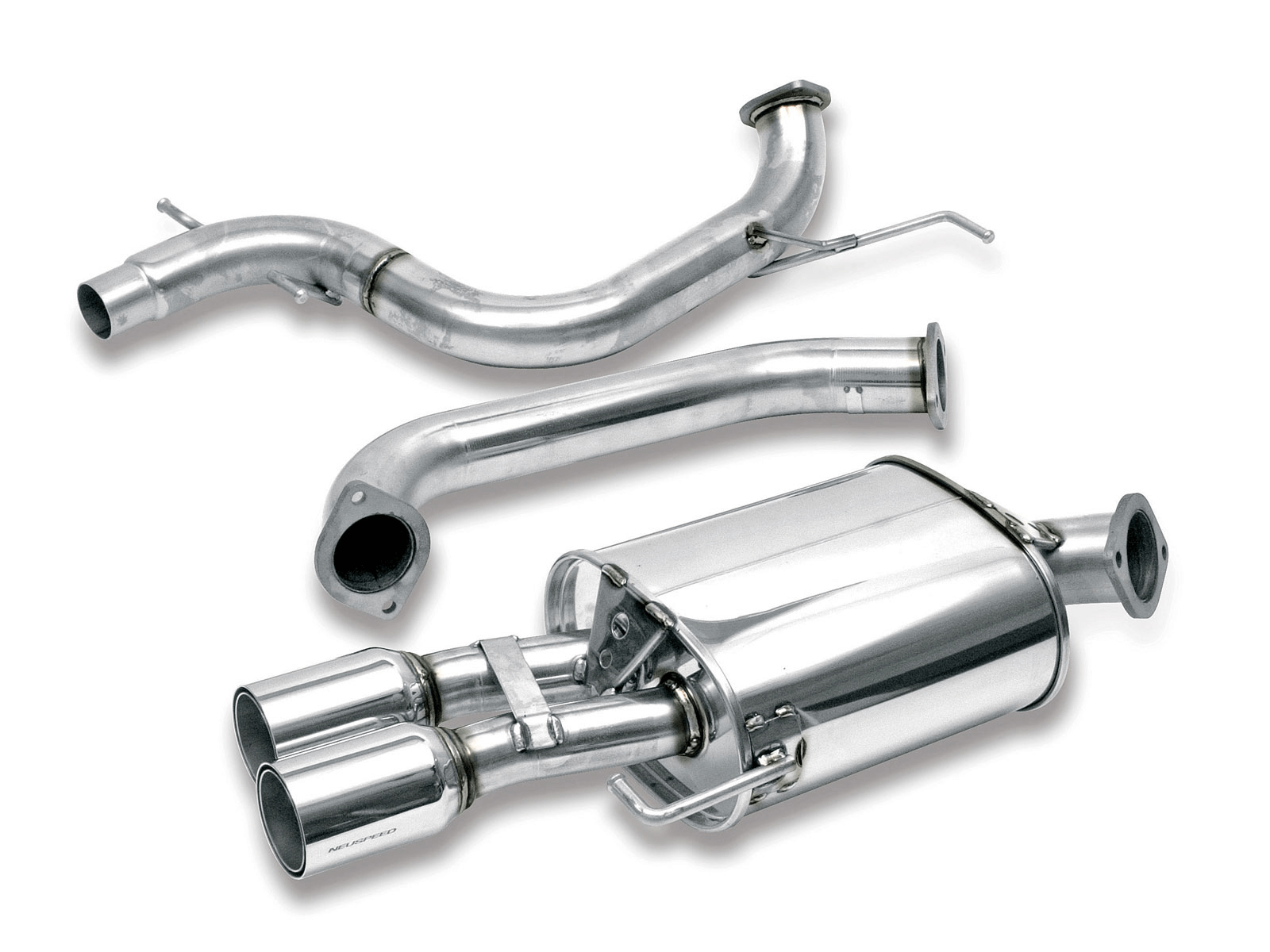

Manifold flanges and exhaust hardware that won't warp or crack under heat. We use the right materials and machine them to last in high-temperature applications.

Turbo housings and compressor components machined to aerospace tolerances. When you're pushing boost, every thousandth of an inch matters for performance and reliability.

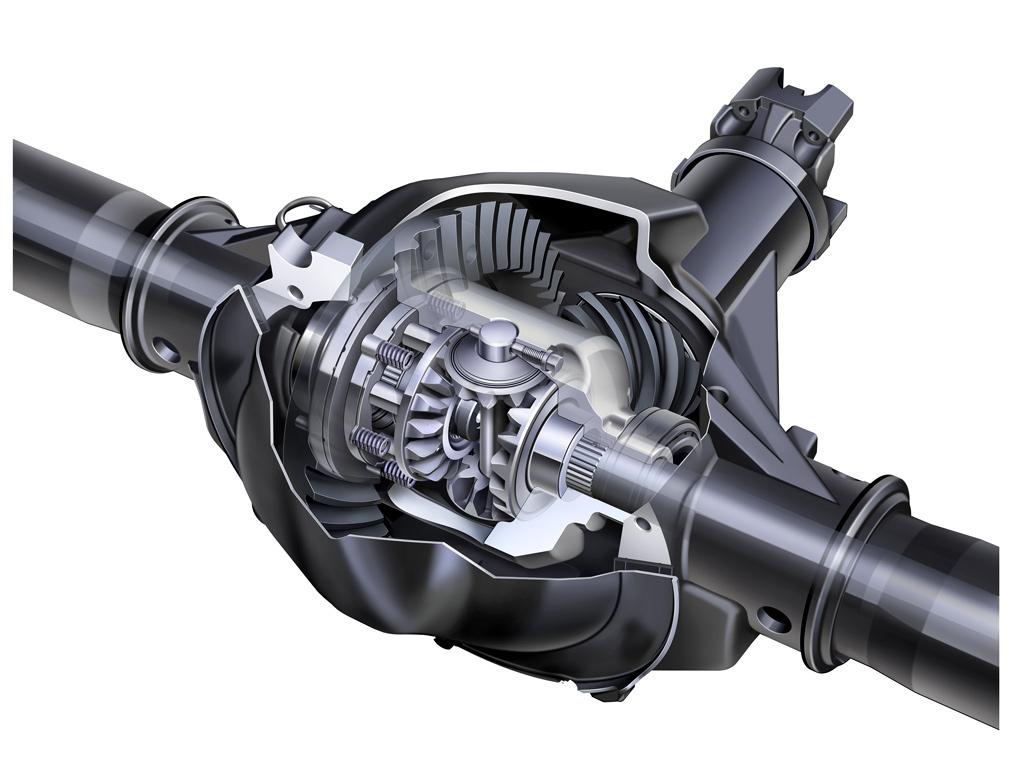

Diff cases, gear carriers, and related hardware built to handle serious power. From street strip cars to dedicated race builds, our differential work stands up to abuse.

Steering racks, pinion gears, and mounting components that give you the precise feel you want. No slop, no play – just clean, responsive steering. Precision you'll feel.

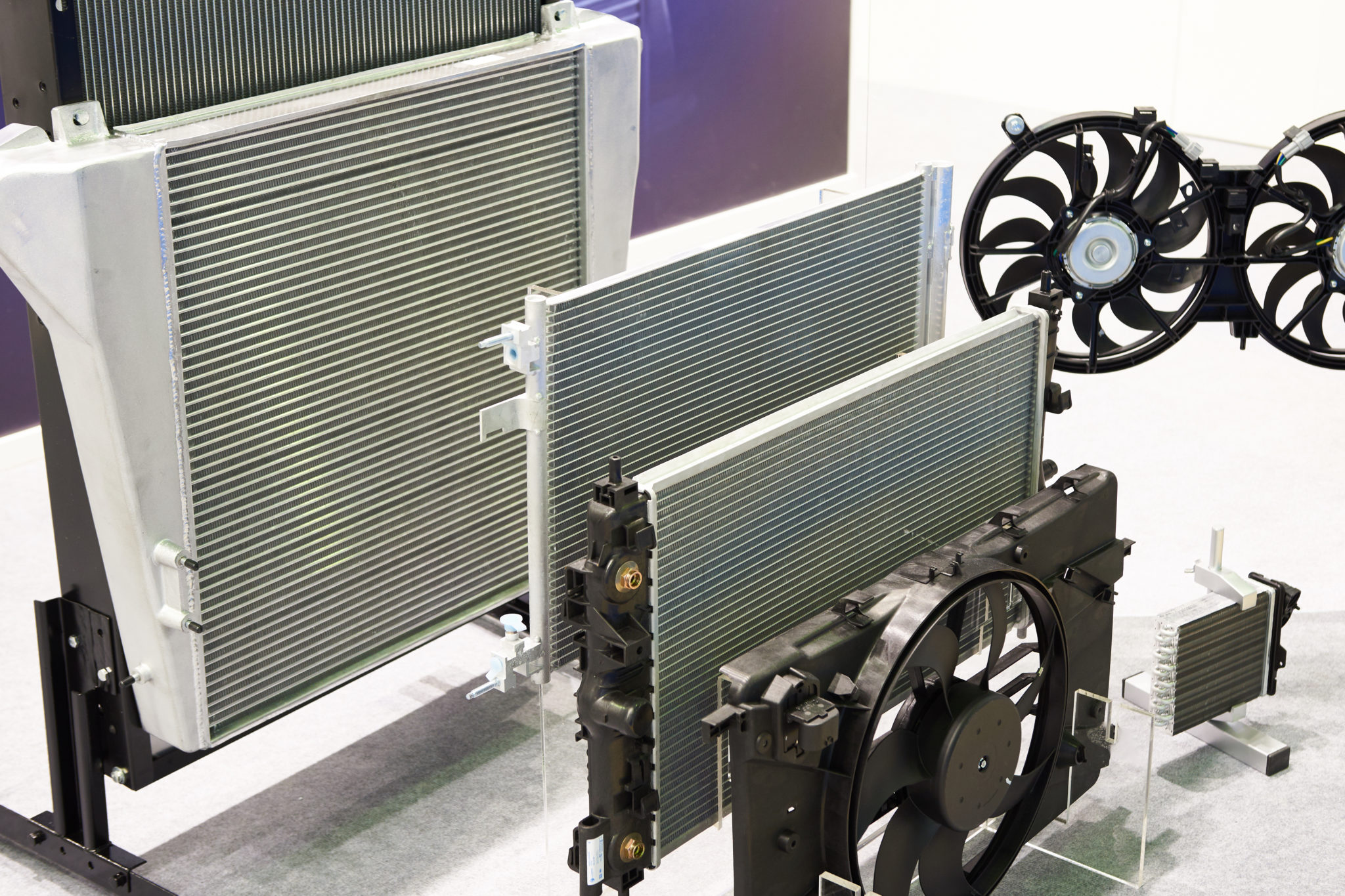

Radiator end tanks, water pump housings, and thermostat components that keep things cool when the heat is on. Proper coolant flow starts with precision machining.

Custom cam profiles, intake manifolds, and one-off performance pieces. When off-the-shelf won't cut it, we machine the parts that make the difference on track.

Race-proven parts for teams that can't afford failures. From club racing to professional motorsport, our components deliver results with pricing that works for any racing budget.

We hit standard tolerances of ±0.01mm on most jobs, but when you need tighter work, we can get down to ±0.002mm. Our Mazak and Haas machines are calibrated weekly, and we check everything with our CMM before it leaves the shop.

We work with all the common automotive materials - 6061 and 7075 aluminum, 4140 and 4340 steel, plus stainless grades like 316 and 17-4 PH. For the high-end stuff, we machine titanium and exotic alloys like Inconel. Just depends on what your application needs.

Normal turnaround is 5-15 days depending on complexity. If you're in a bind, we can usually squeeze rush jobs into 2-3 days. Race teams get priority during competition season - we know what it's like when you need parts yesterday.

Absolutely. Every job comes with a full inspection report showing actual measurements versus your specs. We're ISO 9001 certified and can provide material certs if you need them for traceability.

We do everything from single prototype pieces to runs of several thousand. Small batches are our bread and butter, but we've got the capacity for larger production work too. Each job gets the same attention to detail.

Send us whatever you've got - SolidWorks files, AutoCAD drawings, STEP files, or even hand-sketched prints. Our programmers can work with anything. We'll often suggest improvements to make parts easier to machine without compromising function.

Patterson Motorsport

Giuseppe and his team really know their stuff. We needed custom transmission cases for our touring car build, and they nailed the tolerances perfectly. Great pricing too, especially for the quality you get.

Velocity Racing Team

I've been bringing my brake rotor work to Fedele for three years now. They understand that when you're doing 200+ km/h down the back straight, brake components can't have any margin for error. Fair pricing for precision work.

Boost Dynamics

From club racing to professional motorsport, our components have crossed finish lines nationwide. We ship Australia-wide with competitive pricing that won't break your build budget.