Fedele Autocore - Precision Engineering for Australian Agriculture

Fedele Autocore understands the critical role that reliable agricultural equipment plays in farming operations. We manufacture precision components for tractors, harvesters, tillage equipment, and irrigation systems that keep Australia's farms productive. From drive shafts and transmission parts to hydraulic linkages and implement attachments, our components are built to withstand the harsh conditions of agricultural work including dust, moisture, shock loads, and continuous operation.

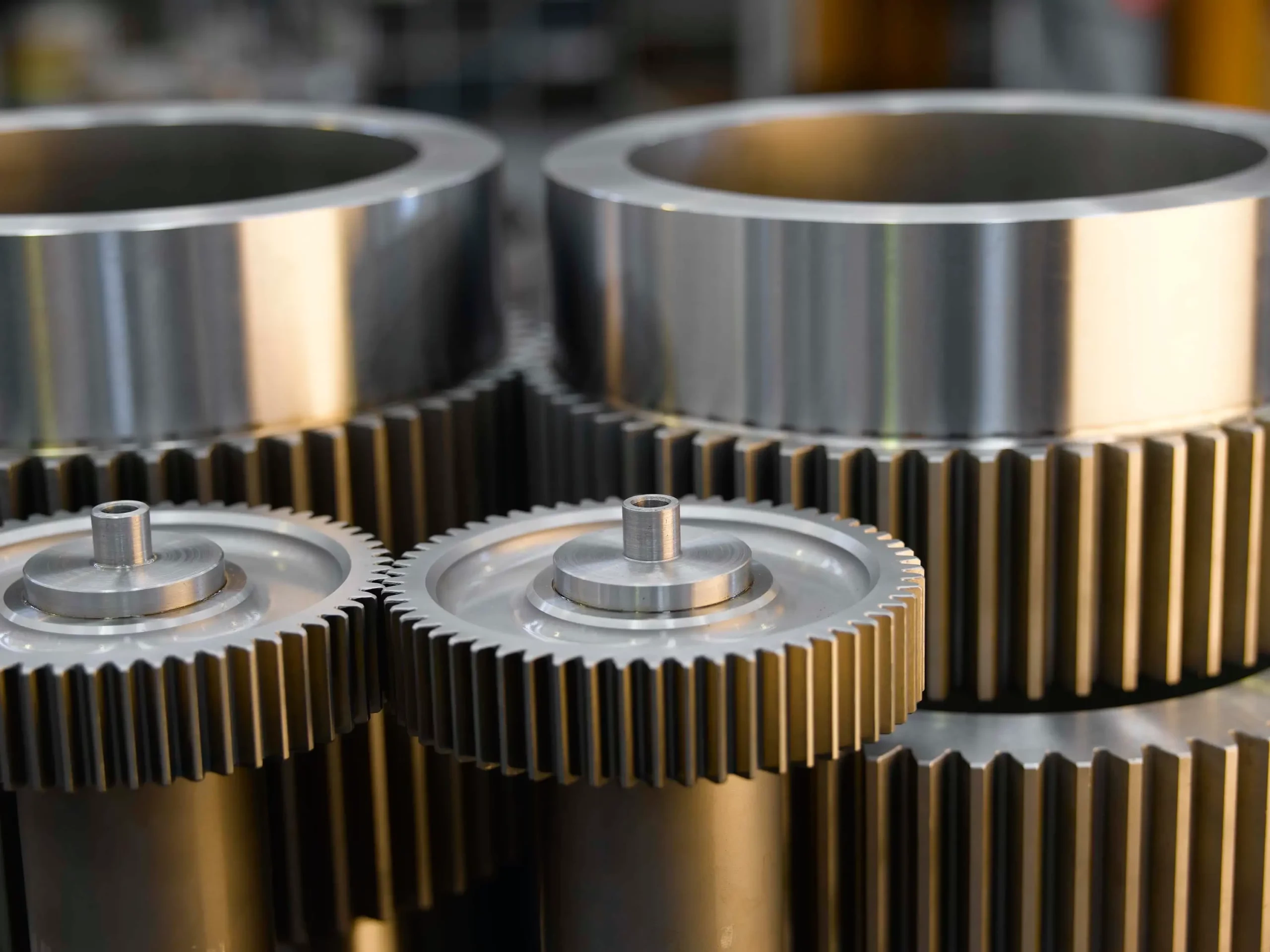

Our manufacturing capabilities support both OEM production and aftermarket replacement parts for major tractor brands and specialized farming equipment. We work with wear-resistant steels, corrosion-resistant materials, and heat-treated alloys to produce bushings, pins, gears, sprockets, and custom machined components that deliver exceptional durability. With fast turnaround times and competitive pricing, we help farmers minimize downtime during critical planting and harvest seasons.

Years Experience

Farm Parts Produced

Quick Turnaround

Precision Tolerance

Fedele Autocore is a leading international manufacturer specializing in precision CNC machining. While our state-of-the-art facilities are located overseas, we proudly serve the Australian agricultural industry with cutting-edge components and unwavering commitment to quality.

With decades of experience in agricultural machinery components, we understand the unique demands of Australian farming conditions. From harsh outback environments to intensive cropping systems, our components are built to last.

Our international manufacturing capabilities combined with dedicated Australian support ensure you receive world-class components with local service excellence. We maintain strategic partnerships throughout Australia for seamless delivery and support.

Our extensive range of precision-engineered components powers Australia's agricultural machinery

Custom hydraulic cylinders for tractors, harvesters, and implements

Precision gears for transmission systems and drive assemblies

Pistons, connecting rods, and crankshaft components

Specialized blades for mowers, choppers, and harvesting equipment

Custom mounting brackets and support structures

Drive shafts, PTO shafts, and rotary components

Wear-resistant bushings for high-stress applications

High-strength bolts, nuts, and specialized fasteners

Cultivator points, discs, and soil engagement tools

Precision fittings for irrigation and spraying systems

We utilize only the finest materials engineered to withstand Australia's demanding agricultural conditions

Superior strength-to-weight ratio, excellent corrosion resistance, ideal for aerospace and high-stress applications.

High corrosion resistance, excellent mechanical properties, suitable for marine and weapon applications.

Lightweight yet strong, excellent machinability, commonly used in aircraft structural components.

Exceptional high-temperature performance, oxidation resistance, critical for jet engine components.

High strength and toughness after heat treatment, ideal for weapon barrels and critical stress components.

Superior high-temperature strength and oxidation resistance for extreme environment applications.

Fedele Autocore maintains strategic partnerships with Australian distributors and service centers, ensuring rapid delivery and local support. Our advanced logistics network guarantees that components reach Australian farms quickly, often matching or exceeding local delivery times. We also maintain inventory in Australian warehouses for critical components.

All our components are manufactured to ISO 9001:2015 standards and undergo rigorous quality testing. We provide full material certifications, dimensional reports, and surface finish documentation. Our components meet or exceed OEM specifications and are backed by comprehensive warranties.

Absolutely! Our engineering team specializes in custom solutions for Australian agriculture. We understand unique challenges like red dirt, extreme temperatures, and seasonal variations. We work closely with Australian farmers and equipment manufacturers to develop components optimized for local conditions.

Standard components: 2-4 weeks. Custom engineered parts: 4-8 weeks. Rush orders can often be accommodated with expedited processing. We maintain strategic inventory levels in Australia to minimize downtime during critical farming seasons like planting and harvest.

Yes, our Australian technical support team provides comprehensive assistance including installation guidance, maintenance schedules, troubleshooting support, and replacement part identification. We offer both remote support and on-site consultation for complex installations.

We specifically select materials based on Australian environmental factors: UV resistance for sun exposure, corrosion resistance for coastal areas, thermal expansion properties for extreme temperature ranges, and abrasion resistance for dusty, sandy conditions. All materials are tested under simulated Australian field conditions.

Our advanced manufacturing capabilities, economies of scale, and efficient supply chain management allow us to offer competitive pricing. Additionally, the superior durability and longevity of our components provide excellent total cost of ownership, reducing replacement frequency and downtime costs.

We provide comprehensive documentation including material certificates, dimensional inspection reports, surface finish analysis, heat treatment certificates (where applicable), installation instructions, maintenance guidelines, and full traceability documentation for quality assurance.