Advanced manufacturing solutions serving Australia's aerospace industry with uncompromising precision and quality

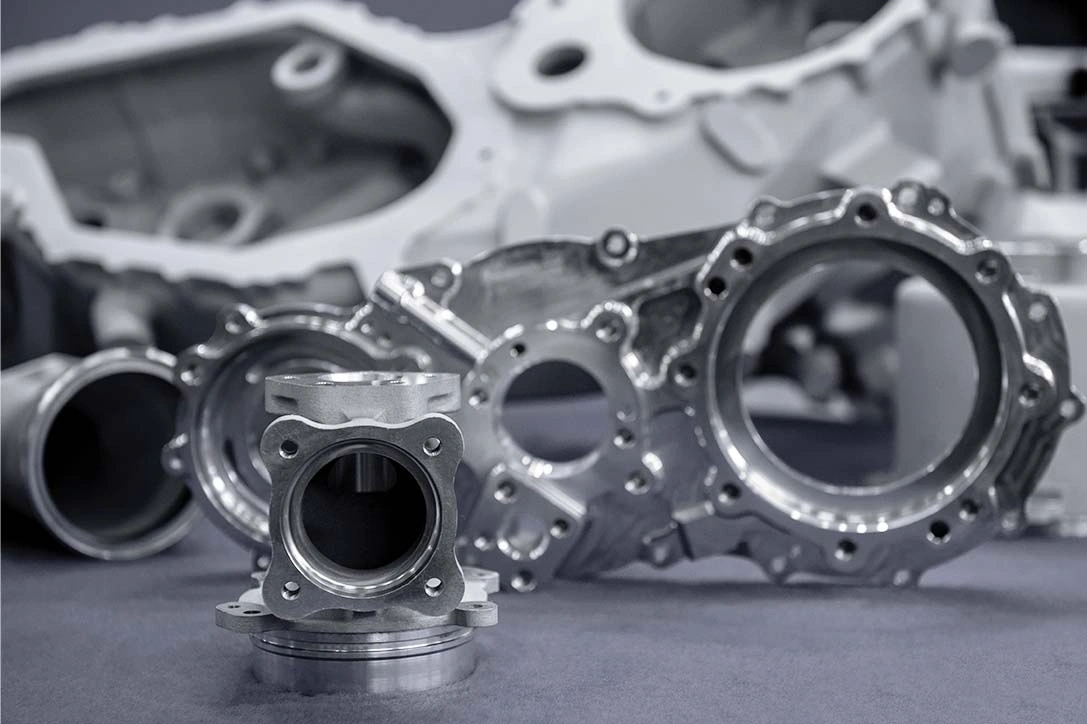

Fedele Autocore brings uncompromising precision and quality to aerospace component manufacturing. We understand that aerospace applications demand the highest levels of accuracy, traceability, and material integrity. Our capabilities include manufacturing structural components, landing gear parts, engine accessories, and flight control system elements that meet stringent aerospace specifications. Every component undergoes rigorous inspection protocols to ensure absolute conformance to design requirements and safety standards.

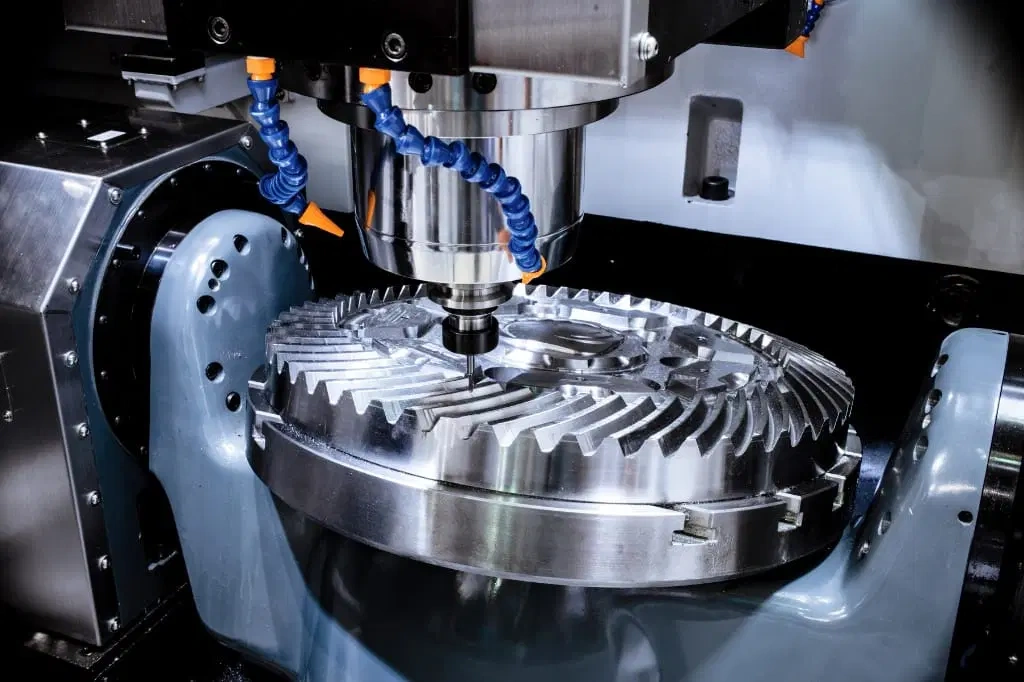

Working with aerospace-grade materials including titanium alloys, aluminum 7075, stainless steel series, and Inconel, our state-of-the-art CNC machining centers deliver components that perform reliably under extreme temperatures, vibration, and stress conditions. We maintain full material traceability and documentation, support AS9100 quality management systems, and implement advanced inspection techniques including CMM verification to ensure every part meets the exacting standards required for aviation and space applications.

Years Experience

Quality Standards

Material Traceability

Precision Tolerance

Our extensive range of precision-engineered components powers Australia's aerospace industry

Turbine blades, compressor discs, fuel injectors, and combustion chamber parts machined to exact specifications with superior surface finishes and dimensional accuracy.

Hydraulic cylinders, actuator housings, shock strut components, and wheel assemblies manufactured with exceptional strength and fatigue resistance.

Wing ribs, fuselage frames, bulkheads, and joint fittings crafted from lightweight alloys while maintaining structural integrity and aerospace standards.

Actuator bodies, servo housings, control surface fittings, and precision linkages ensuring reliable aircraft control system performance.

EMI/RFI shielded enclosures, heat sinks, and mounting brackets protecting sensitive electronic systems in harsh aerospace environments.

Hub assemblies, blade attachments, pitch control mechanisms, and transmission components for both fixed-wing and rotorcraft applications.

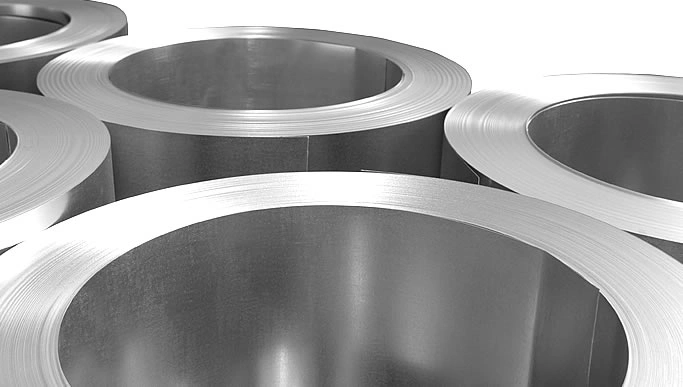

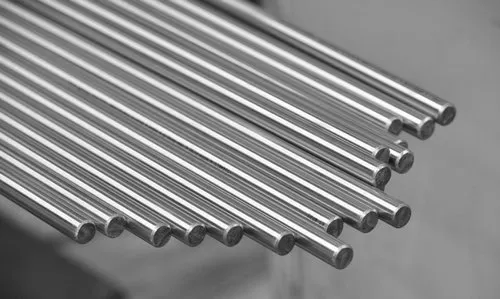

Our expertise spans the complete range of aerospace-grade materials, each selected for specific performance characteristics and application requirements.

Ti-6Al-4V, Ti-6Al-2Sn-4Zr-2Mo for high-strength, lightweight applications with excellent corrosion resistance

7075-T6, 2025-T3, 6061-T6 providing optimal strength-to-weight ratios for structural components

Inconel 718, Waspaloy, Hastelloy X for extreme temperature and pressure applications in engines

17-4 PH, 15-5 PH, 316L for components requiring superior corrosion resistance and durability

4340, 300M, Maraging Steel for high-stress applications requiring exceptional toughness

Cobalt-Chrome alloys, Beryllium Copper, and specialized composites for unique aerospace applications

Aerospace CNC machining requires extraordinary precision, specialized materials, and strict quality control. Components must withstand extreme temperatures, pressures, and vibrations while maintaining critical tolerances. Our processes include rigorous material traceability, advanced inspection techniques, and compliance with aerospace-specific standards like AS9100.

We maintain AS9100 certification and follow CASA regulations for Australian aerospace compliance. Every component undergoes comprehensive inspection using coordinate measuring machines (CMM), with full documentation and certificates of conformance. Our quality system ensures traceability from raw material to final delivery.

Our precision capabilities extend to tolerances as tight as ±0.0001" (±0.0025mm) with surface finishes down to 4 Ra microinches. We utilize advanced 5-axis CNC machines, precision tooling, and climate-controlled environments to maintain these exacting standards throughout production.

Absolutely. We support Australian aerospace companies from initial prototyping through full-scale production. Our flexible manufacturing approach accommodates single prototypes for R&D as well as large production runs, always maintaining the same rigorous quality standards regardless of quantity.

Delivery times vary based on complexity, material availability, and quantity. Simple components may be completed in 2-3 weeks, while complex assemblies or specialized materials may require 4-8 weeks. We provide detailed scheduling during the quoting process and maintain clear communication throughout production for our Australian clients.

Yes, comprehensive documentation is standard for all aerospace projects. This includes material test reports, certificates of conformance, dimensional inspection reports, and full traceability documentation. We maintain detailed records to support Australian aerospace regulatory requirements and customer audit needs.