Built for Power Generation in Turbine Environments

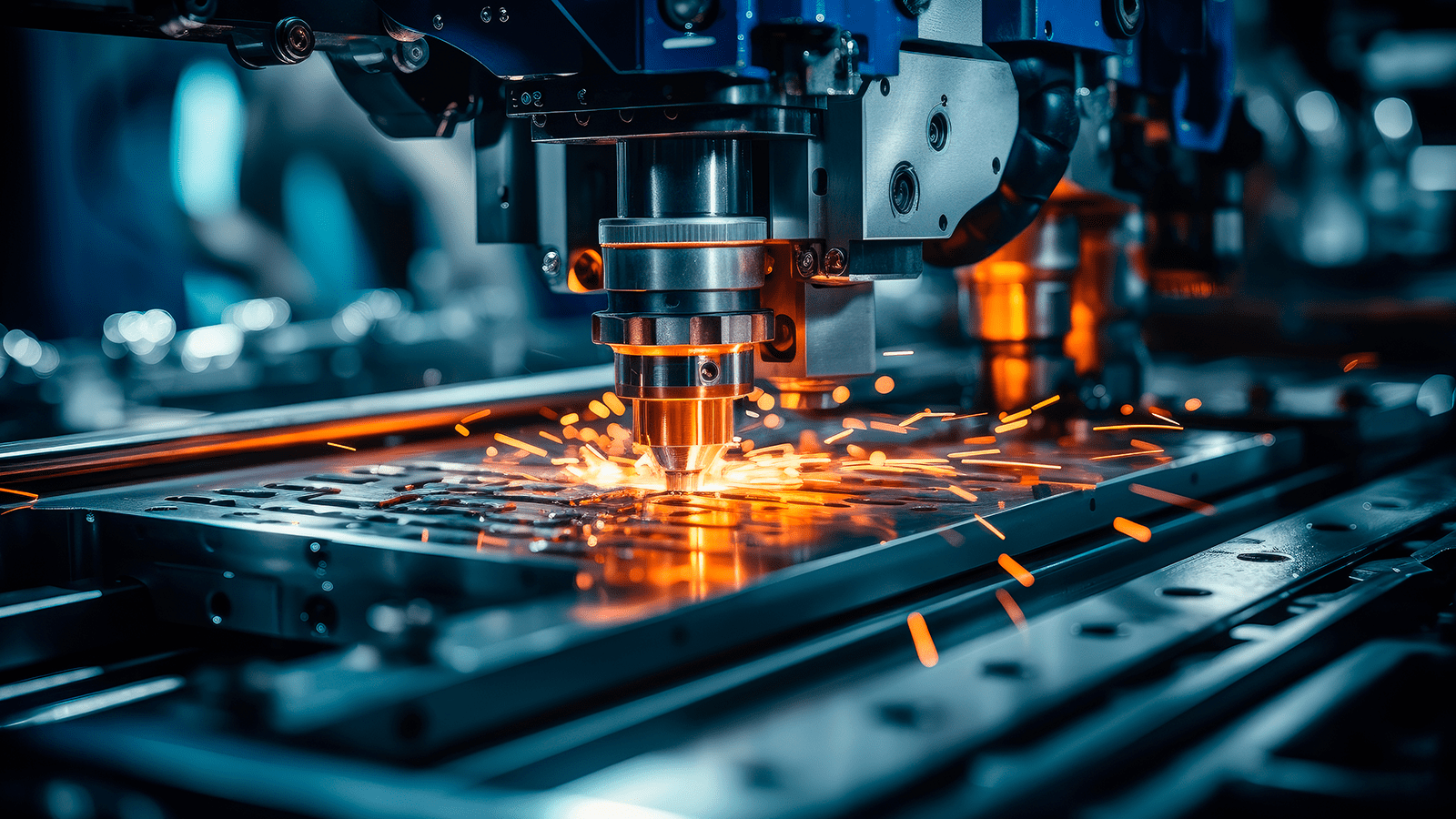

Fedele Autocore delivers precision CNC machining solutions for turbine components used in aerospace, energy, and industrial applications. Our advanced multi-axis machining centers ensure consistent accuracy across complex geometries and high-performance materials.

Each turbine blade, housing, and rotor component undergoes rigorous inspection and thermal stability validation to meet the most demanding tolerance requirements. Our expertise guarantees reliability and efficiency for both gas and steam turbine assemblies.

Precision Tolerance

Thermal Resistance

CNC Machining

Quality Assurance

Complex aerodynamic profiles for maximum efficiency.

Machined to precise balance requirements.

Critical internal geometries for safe operation.

Optimized gas flow and efficiency.

Precision bore tolerances for reliability.

Maintaining critical dimensional accuracy.

Designed for effective thermal management.

Our turbine components require the highest levels of precision machining, often involving 5-axis simultaneous contouring, high-speed machining, and specialized tooling. We maintain capabilities for machining superalloys, titanium, and other exotic materials commonly used in turbine applications.

Turbine components undergo comprehensive inspection including coordinate measurement, optical scanning for blade profiles, dynamic balancing, and non-destructive testing. We maintain traceability documentation and certificates of compliance for all critical components.