Built for demanding applications in Hydraulic Environments

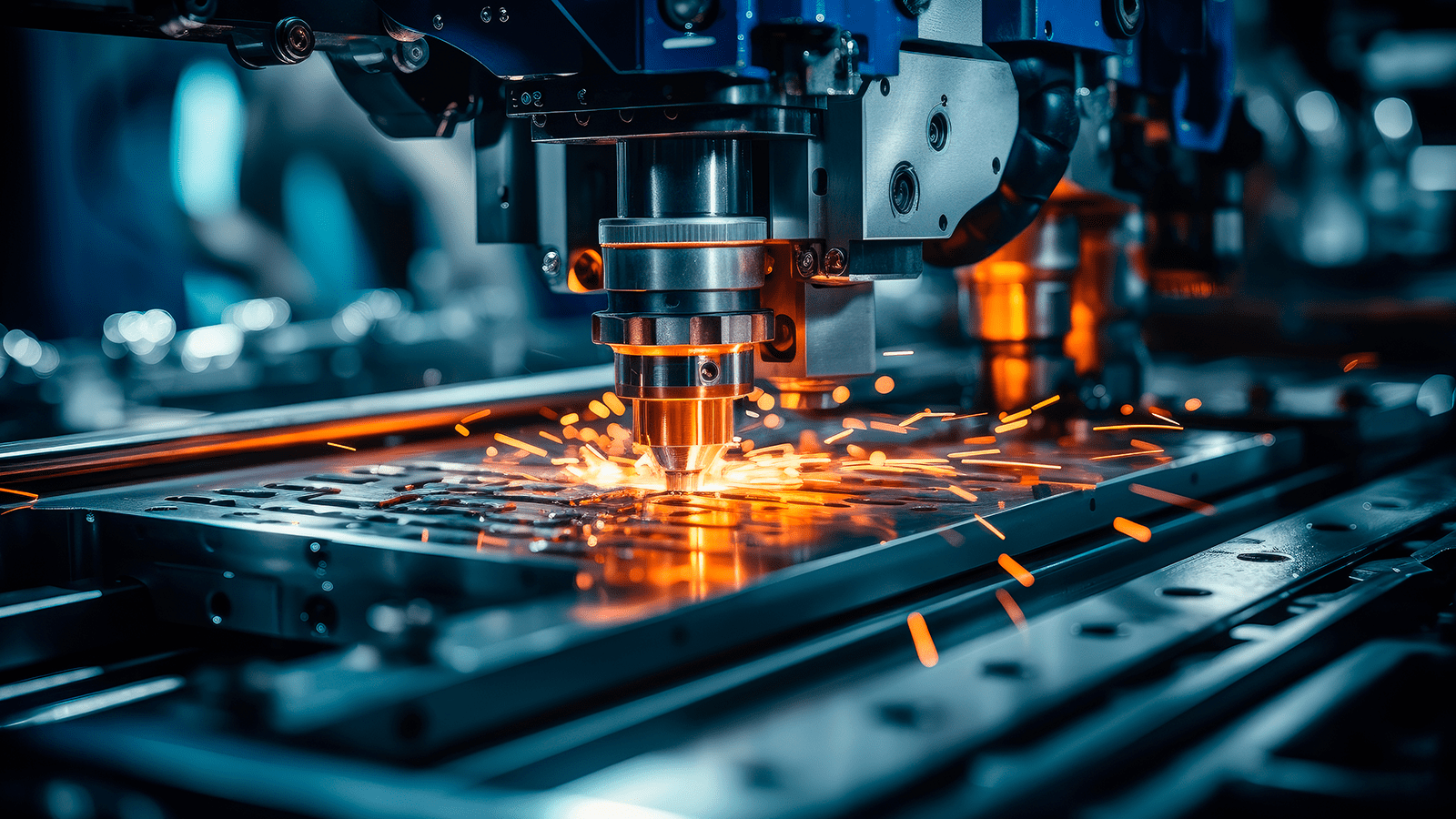

Fedele Autocore specializes in manufacturing precision-engineered hydraulic components that ensure superior pressure control, flow efficiency, and long-term durability. Each part is produced with micron-level precision to meet the exacting standards of the hydraulic systems industry.

Our CNC machining expertise covers a wide range of components including valves, cylinders, manifolds, and fittings. With advanced inspection systems and ISO-certified processes, we guarantee performance, reliability, and leak-free operation for high-pressure hydraulic applications.

Pressure Rating

Dimensional Tolerance

Hydraulic Parts Types

Certified Facility

Intricate internal passages and precise port alignments

Honed to mirror finishes for optimal seal performance

Tight tolerances for minimal internal leakage

Designed for high-pressure operation

Complex internal routing and multiple connections

Precise motion control applications

Flow control assemblies with exceptional durability

Components feature precision-bored cylinders, machined sealing surfaces, and internal passages requiring advanced 5-axis CNC machining.

Maintaining finishes as fine as 8 micro-inches Ra where required for optimal hydraulic performance.

High-strength steels, aluminum alloys, stainless steel, and specialized materials resistant to hydraulic fluids and extreme conditions.

All components receive advanced surface treatments for enhanced durability and corrosion resistance.

Our hydraulic components deliver reliable performance across diverse industries where safety, precision, and durability are critical.