Built for Peak Performance in the Engine Environments

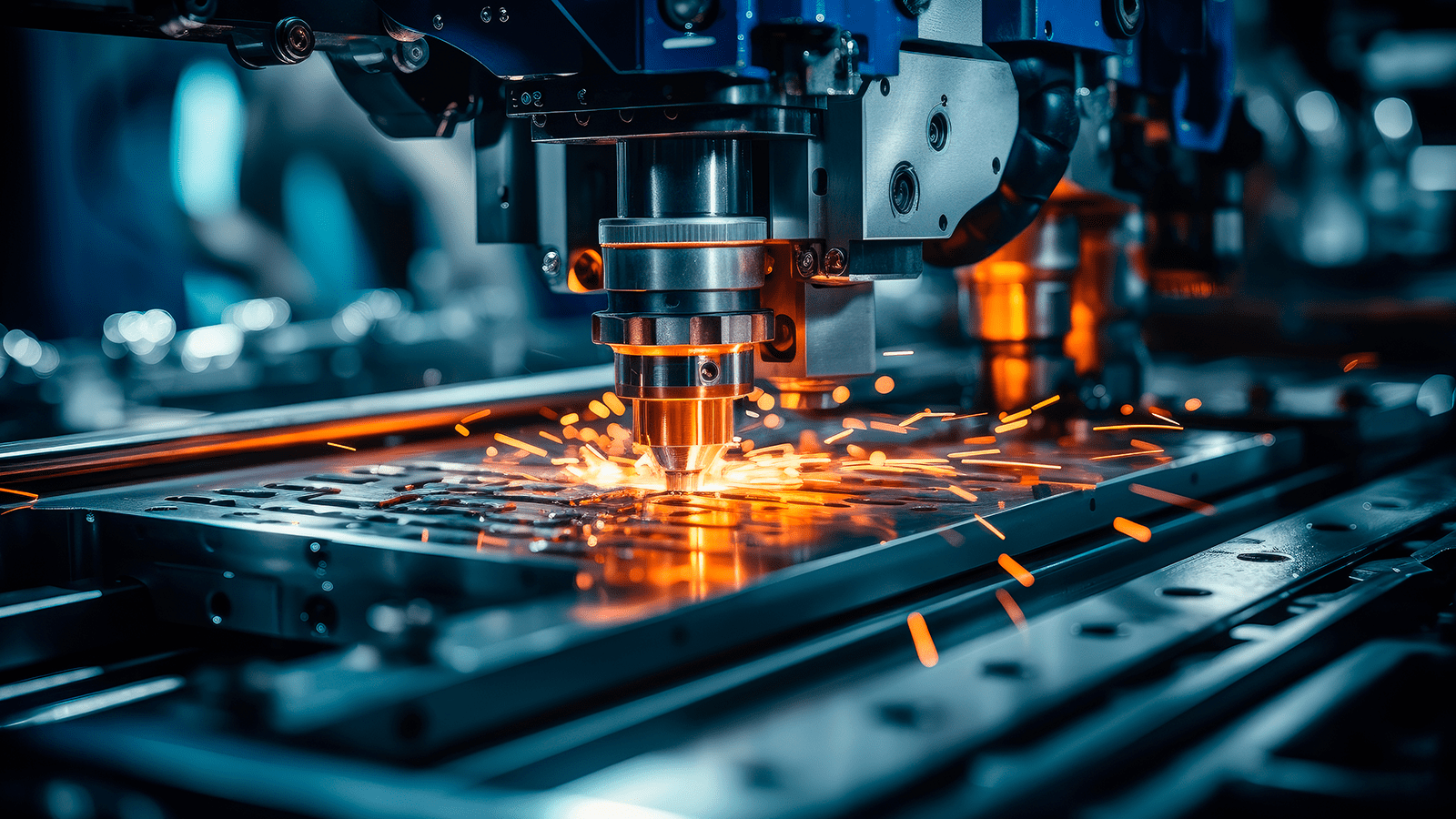

Fedele Autocore excels in producing high-performance CNC machined engine components with uncompromising accuracy and durability. Our expertise spans across automotive, motorsport, and industrial powertrain applications — ensuring every part performs flawlessly under extreme conditions.

Utilizing advanced multi-axis CNC machining centers, precision metrology systems, and material certification protocols, we deliver engine components that meet or exceed OEM and racing specifications. Each piece is crafted to achieve superior strength, minimal friction, and consistent performance at scale.

Machining Accuracy

Engine Parts Designed

Certified Quality

Dimensional Accuracy

Complex cooling passages and valve seats

Precision-machined for durability and strength

Balanced to exacting specifications

Precise lobe profiles for optimal valve timing

Critical bore dimensions and surface finishes

Housings and impellers with precision machining

Designed for maximum flow efficiency

We work with a comprehensive range of materials including aluminum alloys, cast iron, steel forgings, and exotic superalloys. Our heat treatment capabilities and surface finishing processes ensure optimal component durability, wear resistance, and performance characteristics.

Every engine component is manufactured to OEM specifications and beyond, with coordinate measuring machine (CMM) inspection, surface roughness analysis, and comprehensive testing protocols to guarantee performance and reliability.