Built for Performance in the Harshest Drilling Environments

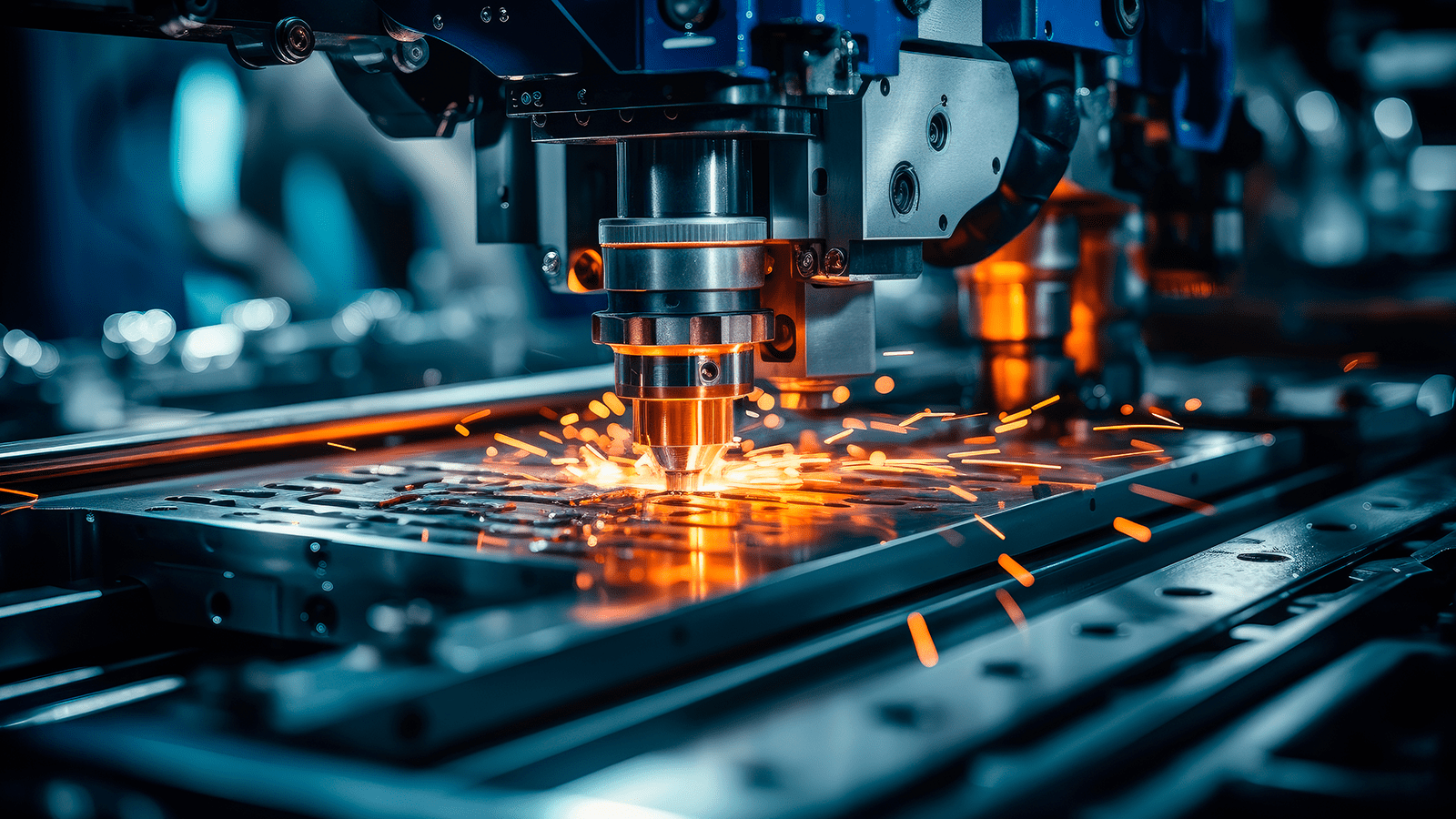

At Fedele Autocore, we specialize in manufacturing high-precision drilling components that meet the demanding requirements of oil and gas exploration, water well drilling, and construction applications. Our advanced CNC machining processes deliver unmatched precision, consistency, and durability in every component.

With cutting-edge machinery and rigorous testing standards, our team ensures superior surface finishes, structural integrity, and performance reliability — even under extreme conditions. Whether for small batches or large-scale runs, we maintain excellence in every production cycle.

Drilling Precision

Material Traceability

CNC Operations

Quality Certified

Superior wear resistance for extended drilling operations

Engineered for extreme pressures and temperatures

Precise mechanical tolerances for reliable operation

Optimal hole geometry and directional control

Rotors and stators with exceptional durability

Critical safety applications with zero-defect quality

Our drilling components are machined from premium alloy steels, hardened tool steels, and specialized materials designed to withstand extreme temperatures, corrosive fluids, and high-pressure environments.

Each component undergoes comprehensive testing including dimensional inspection, hardness verification, and non-destructive testing to ensure reliability in critical drilling operations.

State-of-the-art machining centers with multi-axis capabilities, high-speed machining, and precision tooling systems for complex geometries and tight tolerances.

Engineering support for custom component design, prototyping, and specialized applications with fast turnaround times and competitive pricing.

Our precision drilling components power operations across multiple industries, delivering reliable performance where it matters most.